Mechanical Turntables: Built for Strength, Designed for Accuracy

Mechanical turntables offer a robust and precise solution for industrial applications requiring controlled rotation. Unlike air-bearing turntables, which use compressed air to create near-frictionless movement, mechanical turntables utilize an electric gear motor and a slewing drive to achieve rotation. This mechanical design provides distinct advantages in certain use cases, particularly those requiring multiple precise stopping points.

How Mechanical Turntables Work

At the core of a mechanical turntables strength is a slewing drive powered by an electric motor—typically ranging from 1 to 2 horsepower—providing consistent and controlled rotation. Mechanical turntables allow for direct, programmable control of speed, stopping locations, and load distribution.

Key Benefits of Mechanical Turntables

- Precision Positioning – Mechanical turntables provide exact stopping points, making them ideal for operations requiring multiple rotation positions (e.g., 90°, 180°, or 360° increments).

- High Load Capacities – These turntables can handle significant weight, often exceeding 100,000 lbs, making them suitable for heavy-duty industrial processes.

- Customizable Rotation Control – With an encoder-based control system, users can precisely manage acceleration, deceleration, and stopping accuracy.

- Flexible Design & Size – Unlike air-bearing turntables, mechanical versions can be built in smaller or larger sizes with various table shapes (round, square, etc.).

Ideal Applications for Mechanical Turntables

- Complex Production Lines – Industries requiring multi-step rotation for assembly, weighing, or staging benefit from precise control.

- Robotic Integration – Turntables with programmable stopping points align perfectly with robotic automation in welding, assembly, and packaging applications.

- Heavy-Duty Material Handling – The ability to support high-capacity loads makes mechanical turntables strength ideal for large-scale manufacturing and metal processing.

- Automated Weighing Systems – Some mechanical turntables integrate scales to ensure accurate material measurement at each rotation position.

Design Flexibility & Customization

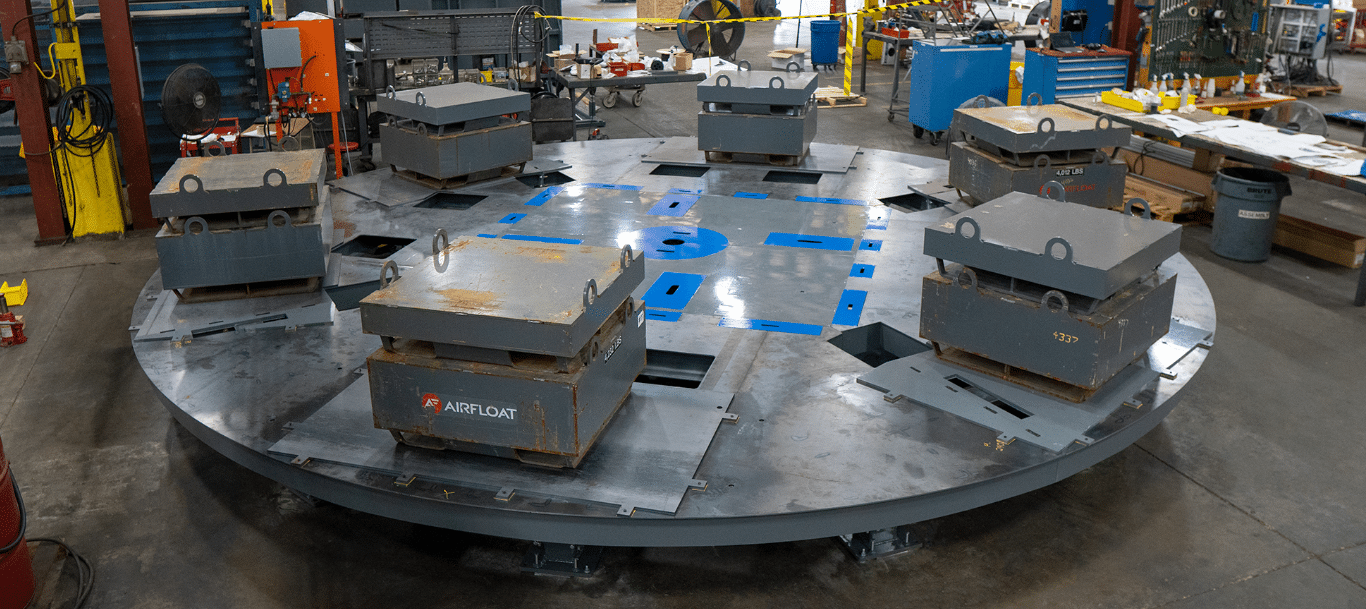

Mechanical turntables offer immense design flexibility. They can be engineered to accommodate different heights, weight capacities, and top configurations. Components such as lifts, integrated weighing systems, and safety enclosures can be added based on customer requirements. Additionally, mechanical turntables can be built in sections for easier transport and assembly, making them suitable for facilities with space constraints.

Maintenance Considerations

Despite their mechanical complexity, these turntables require relatively low maintenance. Maintenance includes:

- Slewing Drive Lubrication – Greasing the drive components every six months to a year ensures smooth operation.

- Electrical Checks – Routine inspections of wiring, slip rings, and motor functions help maintain reliability.

- Structural Inspections – Checking for wear on bolts and drive components ensures continued precision and longevity.

Choosing Between Mechanical & Air-Bearing Turntables

For standard rotational needs between two fixed points (A to B), an air-bearing turntable may be sufficient. However, when multiple stopping points, higher precision, or heavy-duty capacity is required, mechanical turntables provide a superior solution.

If your facility requires a robust, precise, and customizable rotating platform, mechanical turntables from Align Production Systems offer the flexibility and performance necessary for demanding industrial applications.