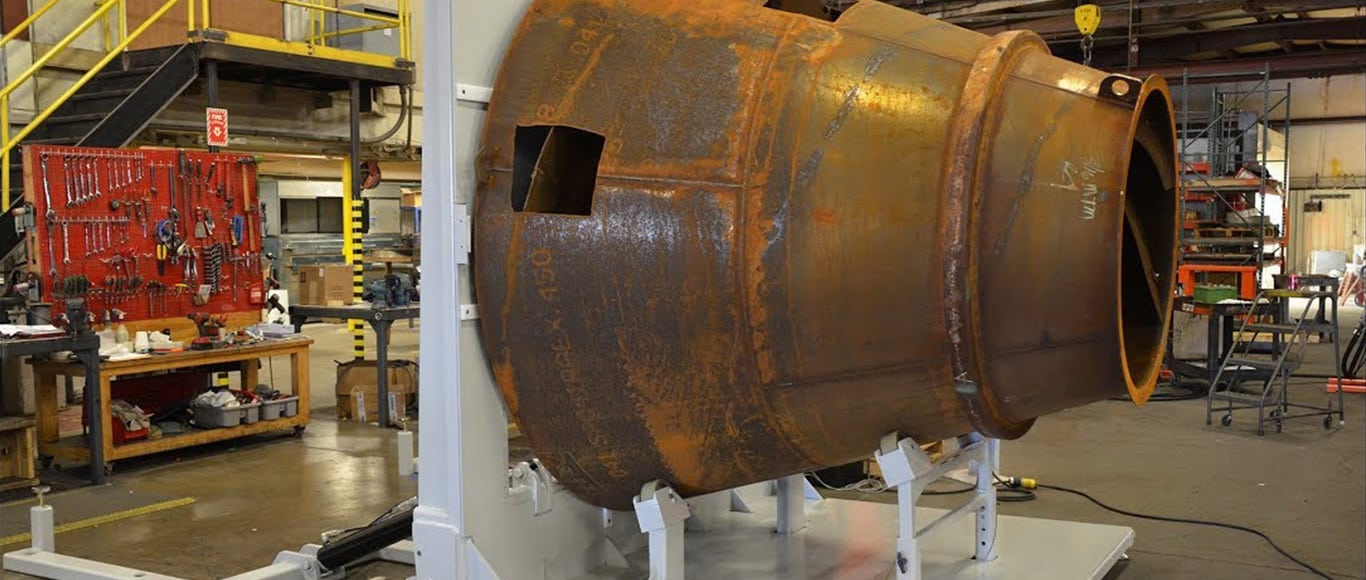

Concrete Mixer

Fabrication

CASE STUDY

THE SITUATION

A manufacturer of concrete mixer trucks needed a better way to manipulate the drums during fabrication. The drum was assembled from two cones, which are moved through fabrication vertically. When the mixing fins are attached to the inside of the drum, the cone needs to be positioned horizontally. After the fins are welded into place, the cone needs to be re-positioned vertically so the two cones can be joined to form the drum.

This process was both time and labor intensive for the manufacturing team, as they had to utilize an overhead crane to tilt the cone into the horizontal position. This method was not only slow, but raised safety concerns. The manufacturer needed a solution that would improve the safety of the process, as well increase production efficiency. They approached their regional tooling specialist for help.

THE SOLUTION

Dave Johnson, The Tool House

The Result

By utilizing Hydraulic Upenders, the manufacturer was able to make the moves in half the time. This improved throughput, as well as eliminated the safety concerns from positioning with an overhead crane.