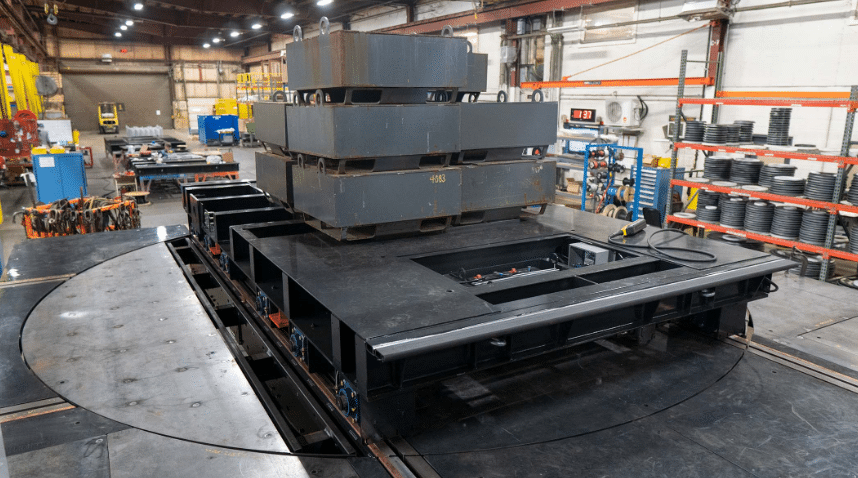

THE SITUATION

Our customer was in need of a new system to transport their sensitive product around their facility. The only problem? It’s heavy. In order to move the load, Align Production Systems designed and manufactured a set of turntables and battery powered carts that interact with the customer’s existing rail system. The mechanical turntables would need to be designed to handle the weight of the load and still be able to rotate it towards a new direction of the rail system.