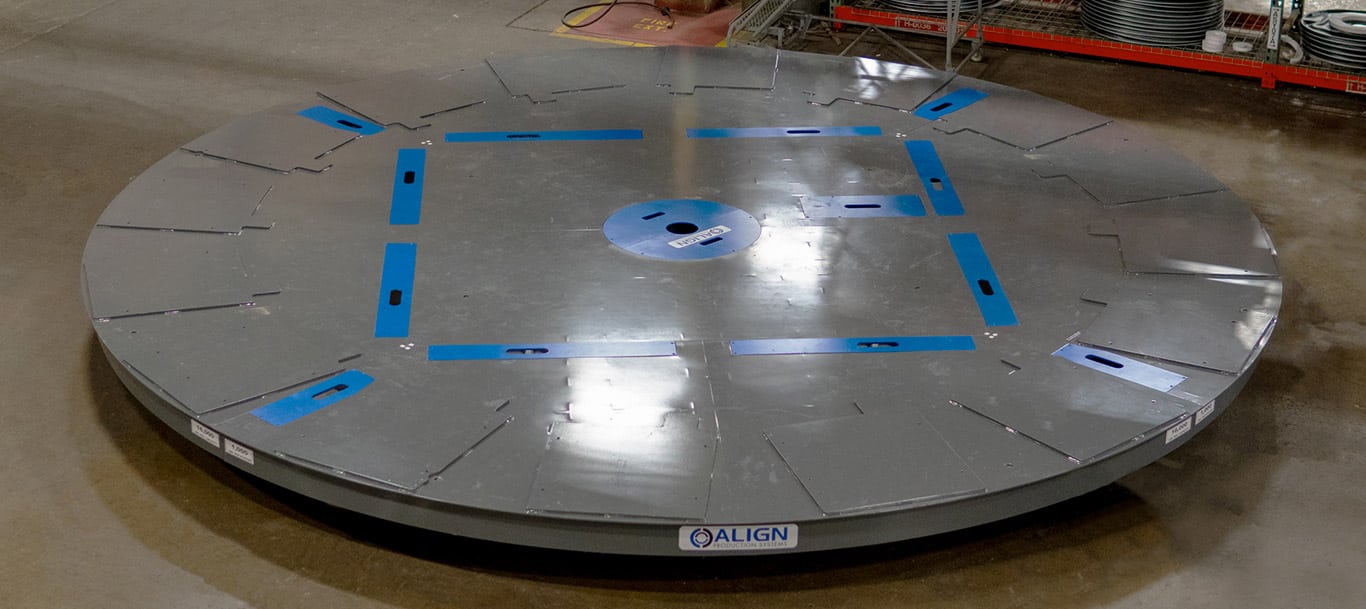

Robotic Indexing

Turntable Assembly Line

CASE STUDY

THE SITUATION

A manufacturer of molded plastic components was looking to optimize their use of a manufacturing robot to remove parts from the molds. They were also looking for a solution that would take up less space than a linear line.

THE SOLUTION

Optimized Efficiency

The custom turntable solution removed production line inefficiencies.

Low Maintenance

Designed with a slewing bearing for continual precision operation.

Heavy Duty

The custom-designed turntables were manufactured to easily rotate 35,000 lbs.

The Result

The turntables improved the production throughput by reducing the time it took to unload products from molds. The unique turntable assembly mold injection line solution also helped the customer save factory floor space.