Custom Industrial Turntables

Specialized Turntables

Custom Industrial Turntables

Custom Industrial Turntables Custom Turntables

Custom Solutions

Maximize Production.

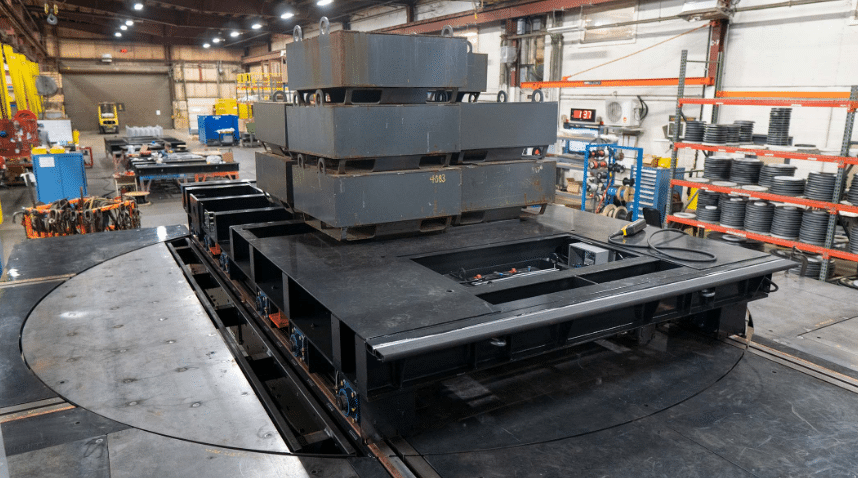

Mechanical Turntables can be used in environments without an air supply as required by our Air Caster Turntables. They’re also great for outdoor areas or situations where the ability to run for an extended amount of time is necessary.

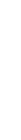

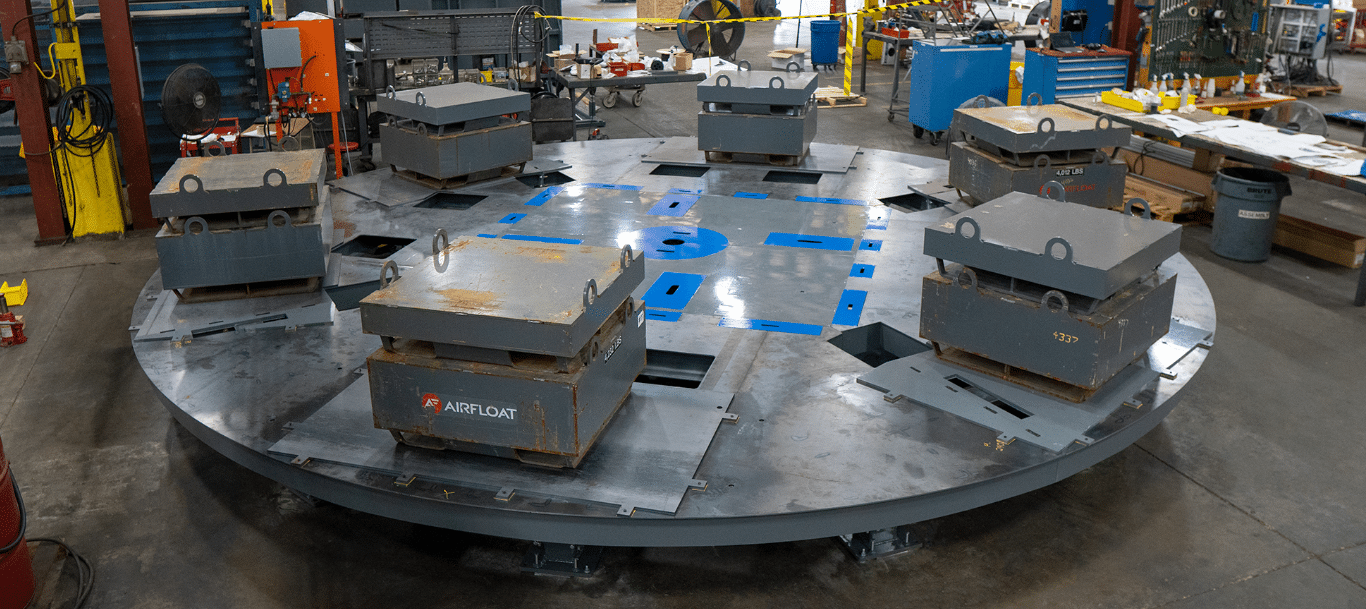

Air Caster technology floats the load on a cushion of air, significantly reducing friction and allowing heavy loads to be rotated with minimal force. Because the Air Caster does most of the work, our tables require few moving parts and experience minimal wear and tear.

When maintenance is needed, our turntables feature slide-out trays for easy access to components. Regular maintenance, as outlined in the manual, and using the proper air settings with a clean and dry air supply, will prolong the lifespan.

We designed our Air Caster Turntables to make it simple and quick to replace all internal components; such as the drive, shock stops, the shot pin, and the air casters themselves.

In certain manufacturing environments, small particles such as glass or dust can cause downtime when using Mechanical Turntables. Air Casters offer a barrier of protection from small particles, resulting in higher efficiency over time. Give us a call at 800-888-0018 to speak with us about which type of turntable would best suit your needs.

Back to Turntables

Back to Turntables