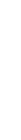

Air Caster Turntables

Rack Handling Solution

Air Caster Turntables

Air Caster Turntables Eliminate End-of-Line Bottlenecks

Enhancing Efficiency in Every Rotation

A low-cost industrial Turntable

Air Caster Turntables and Mechanical Turntables have similar functions, but Air Caster Turntables offer unique advantages. Generally more cost-effective, Air Caster Turntables float the load on air, making rotation easy without the need for expensive components. Their low-profile design keeps the table well below OSHA step-up requirements. Slide-out components make maintenance and replacements quick and easy. While Air Caster Turntables are precise enough for robotic applications, Mechanical Turntables are preferred for extremely high-precision tasks. Both Air Caster and Mechanical Turntables come in a wide range of sizes and capacities, with custom options available.

Air Casters, also known as Air Bearings, are pneumatic devices that create a lubricating film of air between the load and the floor. This cushion of air enables heavy loads to be lifted and moved with minimal friction, allowing for easy positioning of difficult loads with omnidirectional movement. Typically compared to a hovercraft or an air hockey table, think about how the air hockey puck can easily glide across the table with little effort.

The Advantages of an Air Caster Turntable:

+ Low Friction: Makes moving heavy loads easy by floating it on a cushion of air.

+ Capacity: Handling heavy loads, up to 16,000 pounds, with custom available.

+ Enclosed: Keeps the internal components safe & ensures optimal caster performance.

+ Maintenance: Few moving parts and slide-out components ensure easy maintenance and replacements when needed.

Air Caster Turntables have several key safety features. They naturally separate your employees from machines like forklifts and robotic systems, and we offer options like center fences for complete separation. The low-profile design keeps the table well below OSHA’s maximum step height requirements. In an emergency, cutting off the air will quickly and gently set the load down. Without air going to the Air Casters, the steel turntable top sits against the steel base, ensuring the table won’t move.

Our Air Caster Turntables don’t require specific flooring conditions because the Air Casters are enclosed within the turntable. This design protects the casters from debris that could cause damage and ensures the best performance on a smooth steel surface.

Back to Air Caster Turntables

Back to Air Caster Turntables