Built with Align

Industries

Automate the assembly of the world’s largest and heaviest vehicles with AGV capacities over 1,000,000 lbs. Eliminate dangerous assembly processes and improve safety and efficiency with AGVs.

+ Automate the transportation of truck chassis

+ Reduce dangerous moves & keep large chassis on the AGVs

+ Increase safety via creep zones and various scanners to keep operators safe

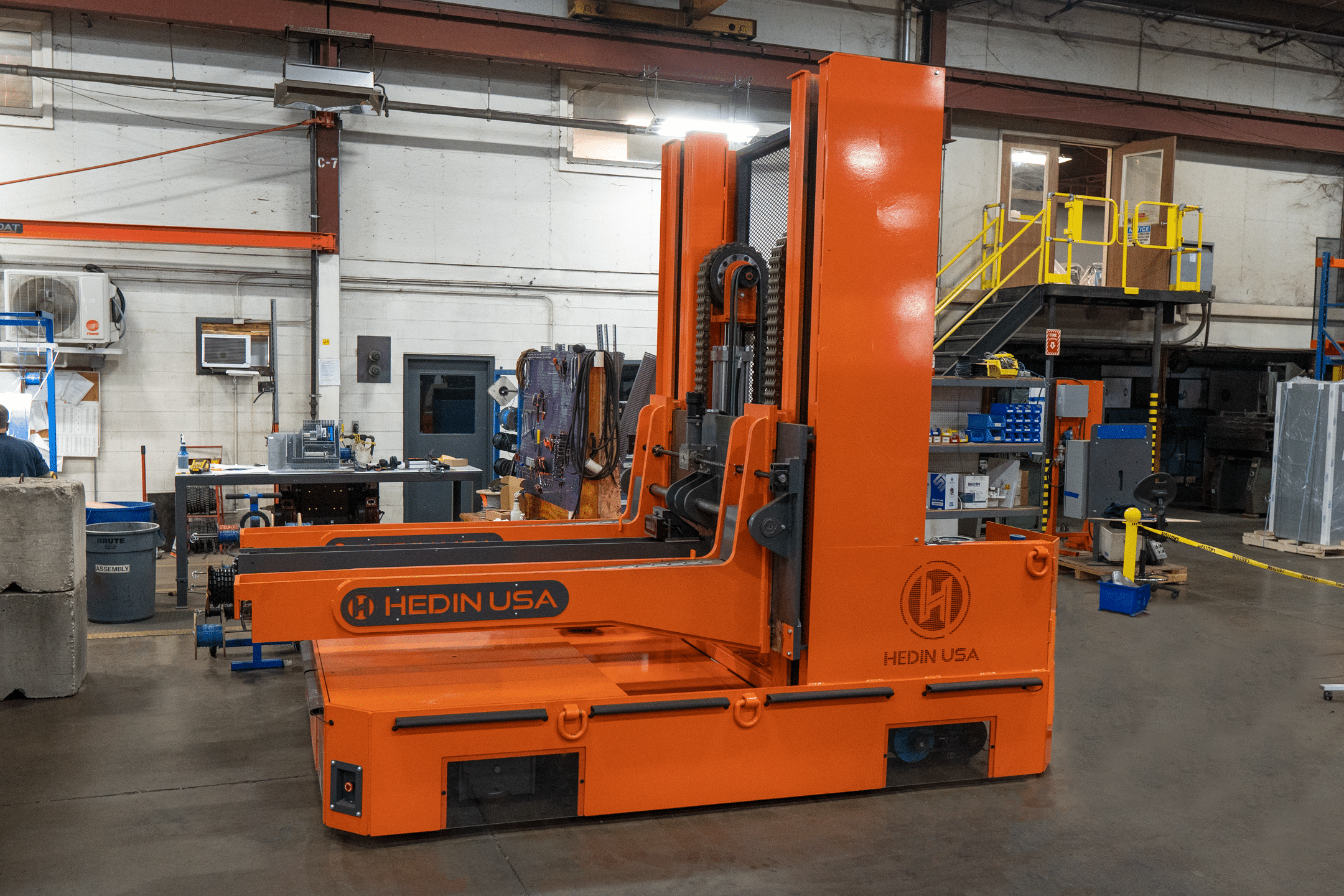

Steel coils are heavy and dangerous to move when using overhead cranes. Coil Cars and Coil Tippers create a safer, more automated alternative for maneuvering and positioning steel coils.

+ Eliminate overhead crane operations

+ Increase safety and assembly efficiency

+ Higher throughput with less time wasted positioning coils

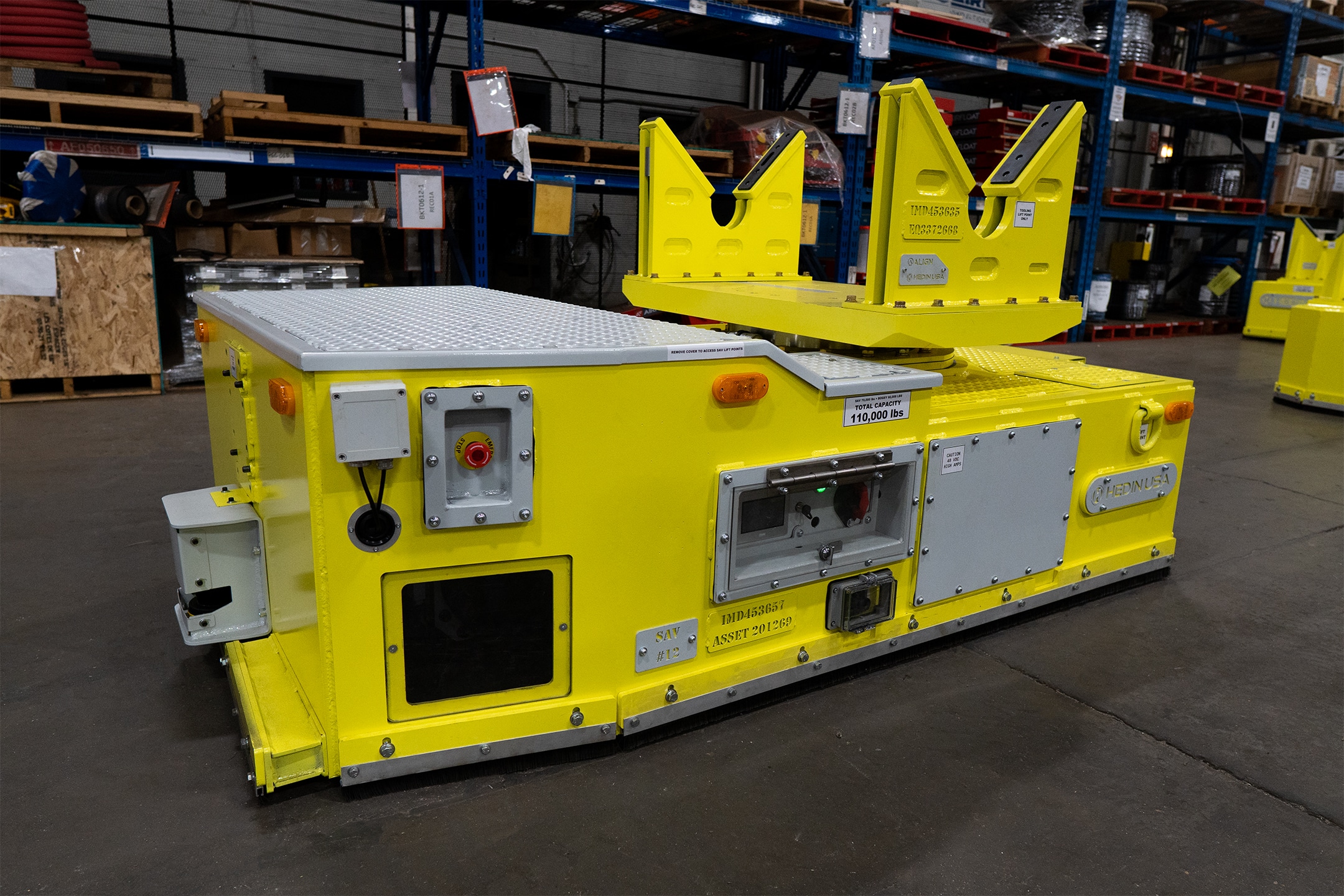

Maneuver wind turbine blades and nacelles with AGVs to automate the production of clean energy machinery. Align provides fully automated solutions with AGVs or manual, lower cost solutions.

+ No emissions for even cleaner production

+ High capacities for even the largest turbines

+ If not AGVs, hand-driven tuggers can also be used

+ Blades can be moved with multiple units

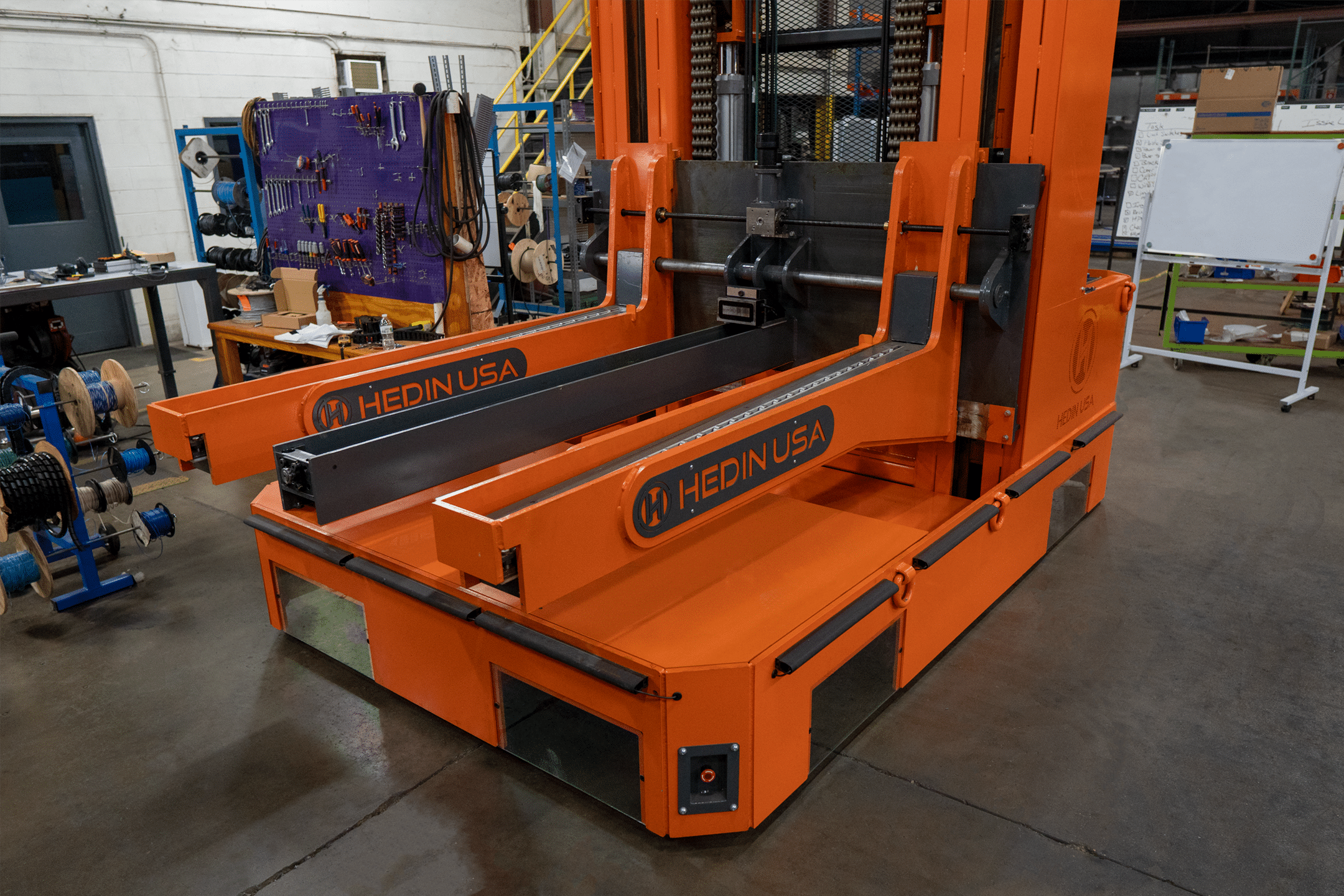

High capacity cable reel maneuvering, with adjustable indexing arms that lift rolls off the ground to eliminate the need for cranes or forklifts.

+ Adjustable arms for a wide range of drum & reel sizes

+ Powered rollers to reel & unreel cable drums

+ AGV capabilities to enable automated production

AGVs and material handling equipment for maneuvering large tractor chassis and agricultural vehicles. Eliminate inefficient moves, reduce operators on the floor, and improve process safety by moving to a more automated system.

+ High capacities AGVs up to – or over 1,000,000 lbs.

+ All-electric units eliminate emissions for clean operation

+ Automate production and reduce dangerous move

Speed up the mold switching process and eliminate lengthy and dangerous mold & die changes. Custom racks can be built by Align for efficient storage of molds & dies.

+ Reduce downtime, quickly swap molds with ease

+ Roller bed with loading arms to insert & extract molds

+ Saving space with stacked mold & die storage

+ Adjustable height for different loading & unloading heights

Maneuver fuselages or satellites throughout the assembly process by utilizing all-electric transporters. Airfloat Air Skids have also been used aerospace applications, including transporting the Boeing / NASA Starliner throughout assembly.

+ Automate fuselage assembly and keep the line moving efficiently

+ Other Align family products, like Air Skids or Lift Glides, are proven solutions

+ Increase worker safety with less dangerous equipment

AGVs keep the line moving as efficiently as possible, featuring opportunity charging to keep operations running 24/7 with no charging downtime and all-around safer assembly lines.

+ All-electric & no emissions for clean, indoor operation

+ Safety features reduce operator risk

+ Fully automated assembly for increased throughput

+ Adjustable height for different loading/unloading heights