Glass Rack

Handling

CASE STUDY

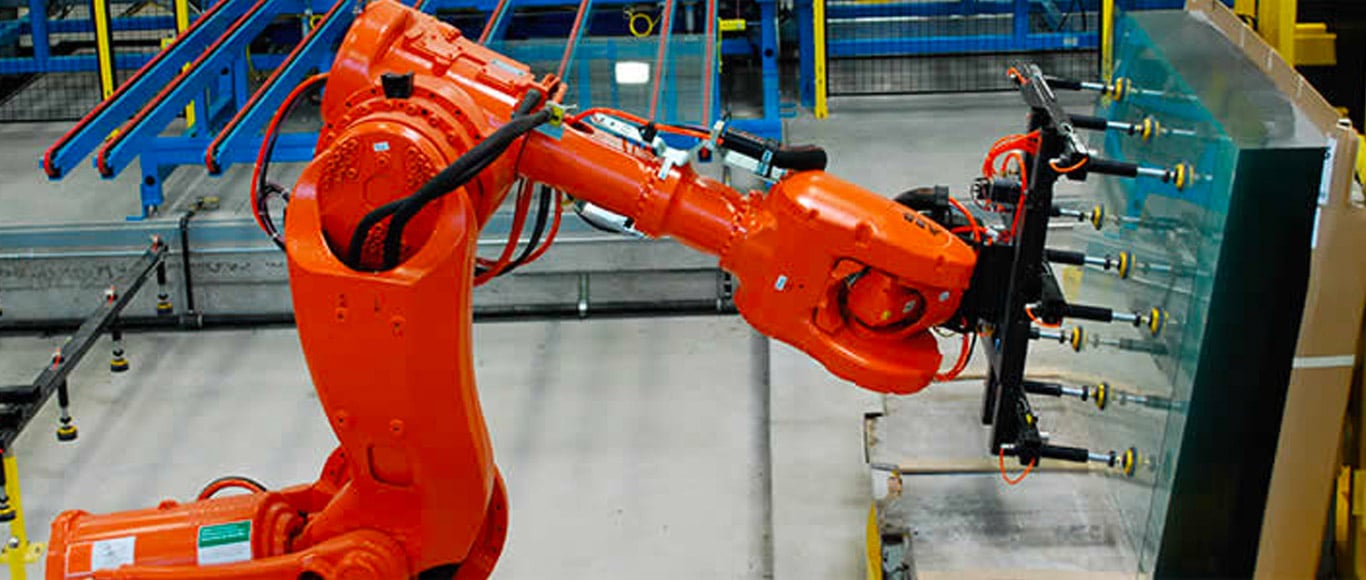

THE SITUATION

A glass manufacturer was looking to optimize the end of line racking for their automated flat glass manufacturing line. The glass racking at the end of line required a racking system that could operate without pauses between loading/unloading racks.

A roadblock with integrating a turntable into the line was glass dust. The glass dust would penetrate bearings, causing costly downtime.

THE SOLUTION

The Result

Align Production Systems’ robotic interfacing turntables increased throughput on the glass manufacturing line by eliminating pauses in production that occurred when changing racking. The air caster powered units also reduced downtime by 95% by eliminating damage caused by glass dust.