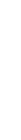

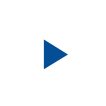

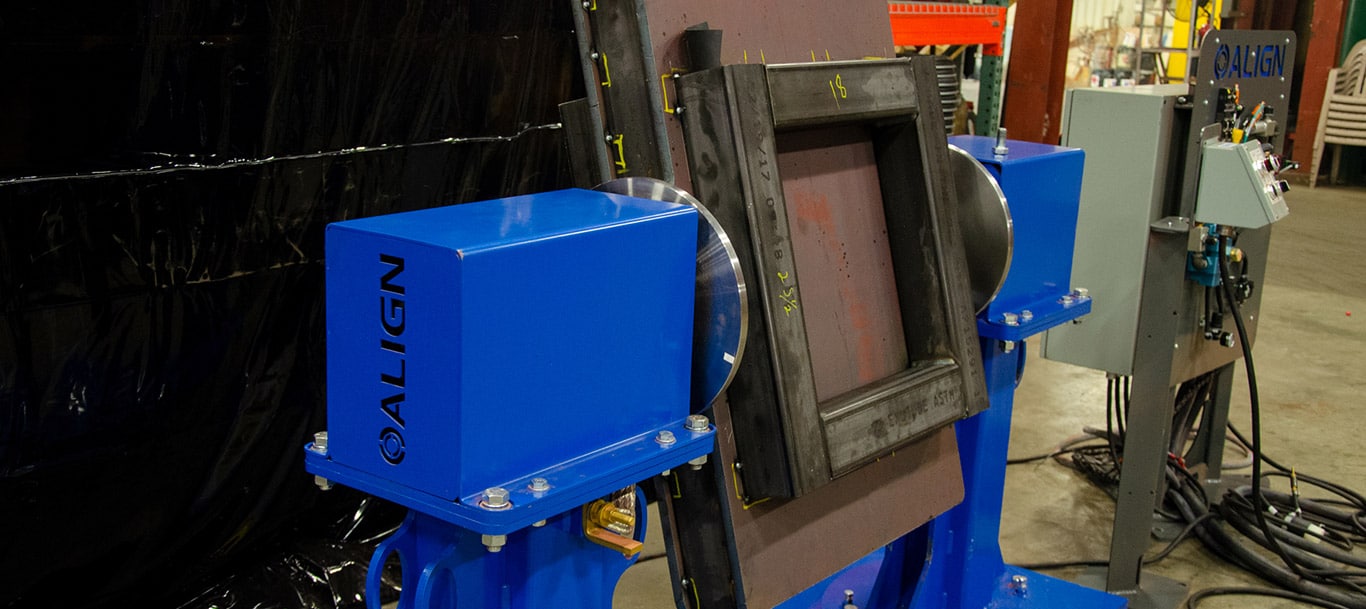

Adjustable Head and Tailstock

Position & Weld

Adjustable Head and Tailstock

Adjustable Head and Tailstock Adjustable Head & Tailstock

|

Model No.

Model No.

|

Capacity (lbs)

Capacity (kgs)

|

Vertical Travel (in)

Vertical Travel (mm)

|

Travel Speed (in)

Travel Speed (mm)

|

Torque (in/lb)

Torque (nm)

|

RPM

RPM

|

Center Height (in)

Center Height (mm)

|

Optional Grounding (amps)

Optional Grounding (amps)

|

|---|---|---|---|---|---|---|---|

|

Model No.

Model No.

APS021-008

APS021-008

|

Capacity (lbs)

Capacity (kgs)

8,000

3,600

|

Vertical Travel (in)

Vertical Travel (mm)

60

1524

|

Travel Speed (in)

Travel Speed (mm)

1.7 - 34.0

43 - 864

|

Torque (in/lb)

Torque (nm)

48,000

5423

|

RPM

RPM

0.1 - 3.0

0.1 - 3.0

|

Center Height (in)

Center Height (mm)

18 - 80

457 - 2032

|

Optional Grounding (amps)

Optional Grounding (amps)

800A

800A

|

|

Model No.

Model No.

APS021-015

APS021-015

|

Capacity (lbs)

Capacity (kgs)

15,000

6,800

|

Vertical Travel (in)

Vertical Travel (mm)

60

1524

|

Travel Speed (in)

Travel Speed (mm)

1.7 - 34.1

43 - 864

|

Torque (in/lb)

Torque (nm)

75000

8474

|

RPM

RPM

0.1 - 2.0

0.1 - 2.0

|

Center Height (in)

Center Height (mm)

19 - 80

458 - 2032

|

Optional Grounding (amps)

Optional Grounding (amps)

800A

800A

|

|

Model No.

Model No.

APS021-035

APS021-035

|

Capacity (lbs)

Capacity (kgs)

35,000

15,900

|

Vertical Travel (in)

Vertical Travel (mm)

60

1524

|

Travel Speed (in)

Travel Speed (mm)

1.7 - 34.2

43 - 864

|

Torque (in/lb)

Torque (nm)

190000

21467

|

RPM

RPM

.04 - 0.9

.04 - 0.9

|

Center Height (in)

Center Height (mm)

20 - 80

459 - 2032

|

Optional Grounding (amps)

Optional Grounding (amps)

1500A

1500A

|

|

Model No.

Model No.

|

Description

Description

|

|---|---|

|

Model No.

Model No.

APS5040-0100

APS5040-0100

|

Description

Description

Auxiliary Control Option / Pendant / HD Head & Tailstock

Auxiliary Control Option / Pendant / HD Head & Tailstock

|

|

Model No.

Model No.

APS5040-0110

APS5040-0110

|

Description

Description

Auxiliary Control Option / Foot /

HD Head & Tailstock

Auxiliary Control Option / Foot /

HD Head & Tailstock

|

|

Model No.

Model No.

APS5040-0120

APS5040-0120

|

Description

Description

Auxiliary Control Option /

Remote Stand /

HD Head & Tailstock

Auxiliary Control Option /

Remote Stand /

HD Head & Tailstock

|

|

Model No.

Model No.

APS5040-0130

APS5040-0130

|

Description

Description

Auxiliary Control Option /

Wireless Pendant /

HD Head & Tailstock

Auxiliary Control Option /

Wireless Pendant /

HD Head & Tailstock

|

|

Model No.

Model No.

APS5041-0100

APS5041-0100

|

Description

Description

Central Grounding / 800A / HD

Head & Tailstock

Central Grounding / 800A / HD

Head & Tailstock

|

|

Model No.

Model No.

APS5041-0110

APS5041-0110

|

Description

Description

Central Grounding / 1500A / HD

Head & Tailstock

Central Grounding / 1500A / HD

Head & Tailstock

|

|

Model No.

Model No.

APS5043-XXXX

APS5043-XXXX

|

Description

Description

Basic Control Stand

Basic Control Stand

|

|

Model No.

Model No.

APS5045-XXXX

APS5045-XXXX

|

Description

Description

Horizontal Adjustment Rails

Horizontal Adjustment Rails

|

|

Model No.

Model No.

APS5046-XXXX

APS5046-XXXX

|

Description

Description

Vertical Rail Bellows

Vertical Rail Bellows

|

|

Model No.

Model No.

APS5047-XXXX

APS5047-XXXX

|

Description

Description

Horizontal Rail Bellows

Horizontal Rail Bellows

|

|

Model No.

Model No.

APS5049-XXXX

APS5049-XXXX

|

Description

Description

Riser Base

Riser Base

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Audible/Visual Alarm

Audible/Visual Alarm

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Safety Guarding

Safety Guarding

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Conical Locators

Conical Locators

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Error Proofing Pin

Error Proofing Pin

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Rack Present Sensors

Rack Present Sensors

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Custom Controls Package

Custom Controls Package

|

|

Model No.

Model No.

Custom

Custom

|

Description

Description

Custom Tooling Interface

Custom Tooling Interface

|

Maximize Production.

Height & Width

Welding

Electric

No worries. We offer custom engineering and designing to match product specifications to your needs. Contact us at 800-888-0018 to speak with us about custom solutions.

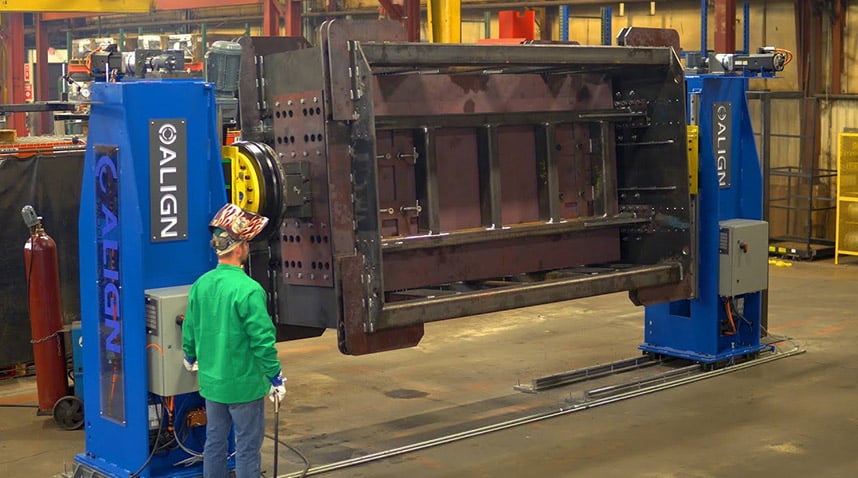

To find the right positioner for your needs, take into consideration the weight of your weldment and understand the features of each of our positioners. The Adjustable Head & Tailstock is our most advanced positioner with height adjustment in addition to weldment rotation while the

Not should you consider the weight, but it’s important to calculate the torque moment based upon the center of gravity of the load.

Back to Welding Positioners

Back to Welding Positioners