Wire, Wire Rope, & Cable Solutions

Wire, Wire Rope, & Cable Solutions

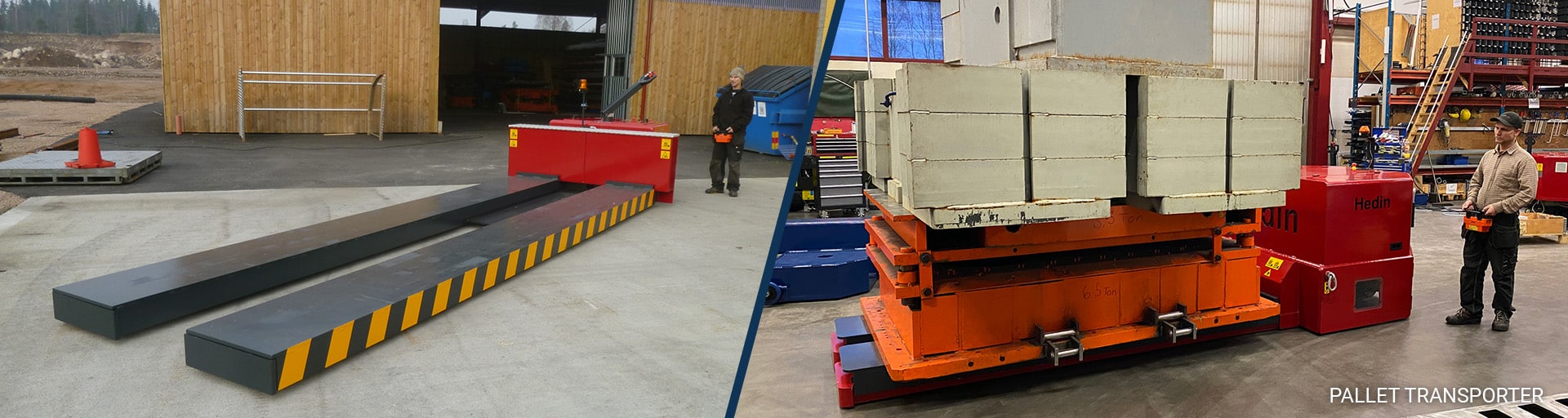

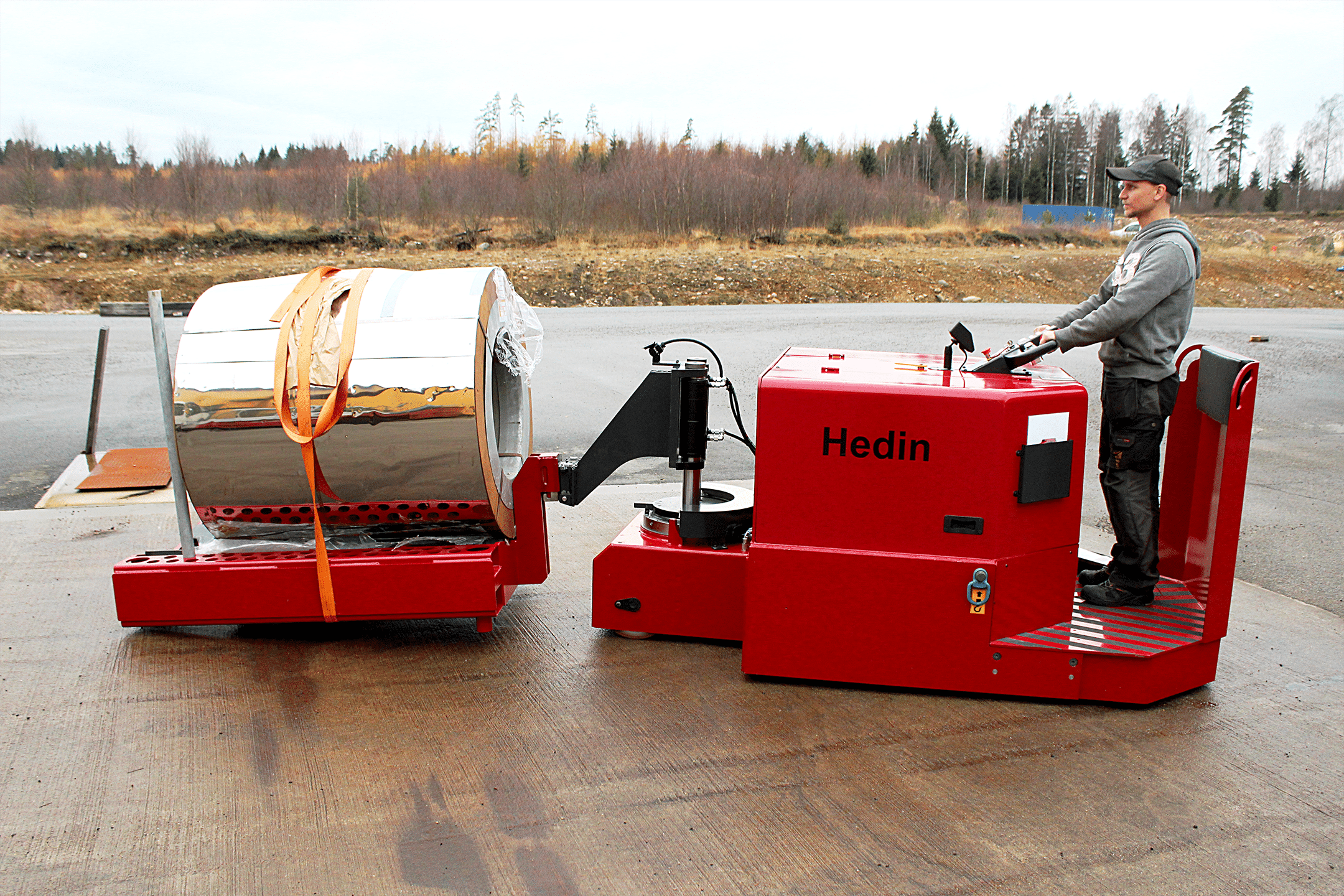

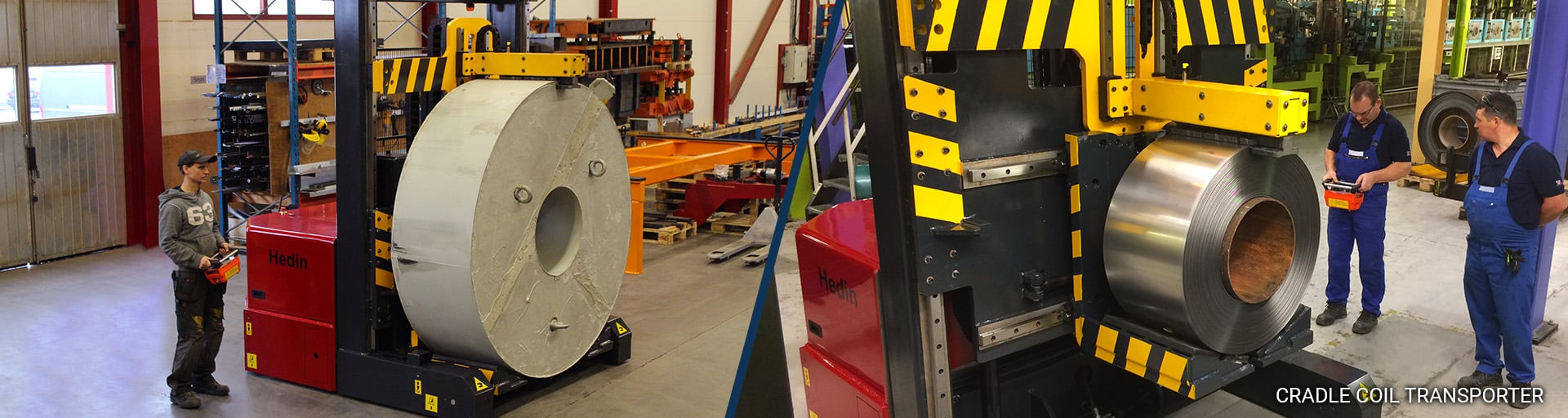

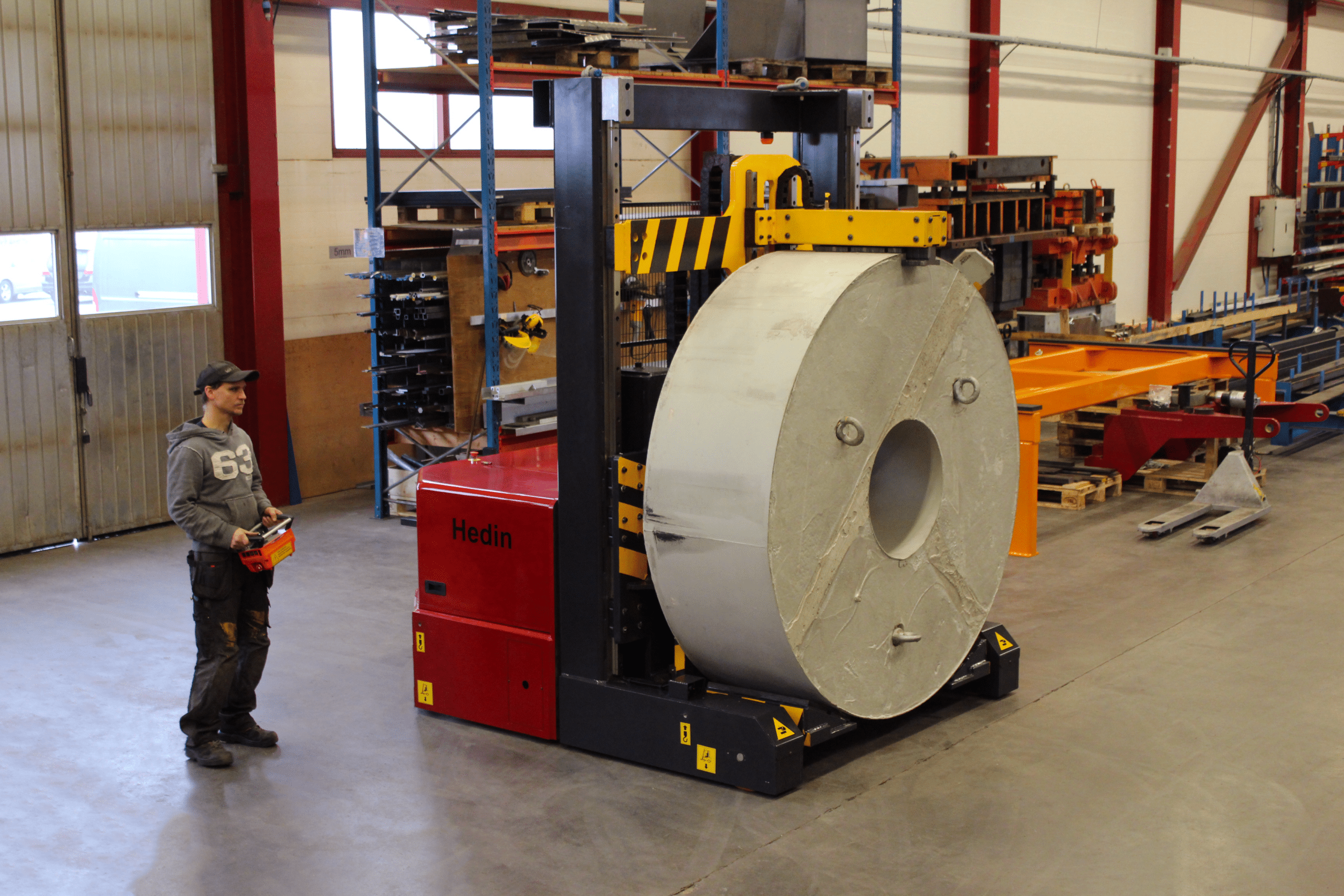

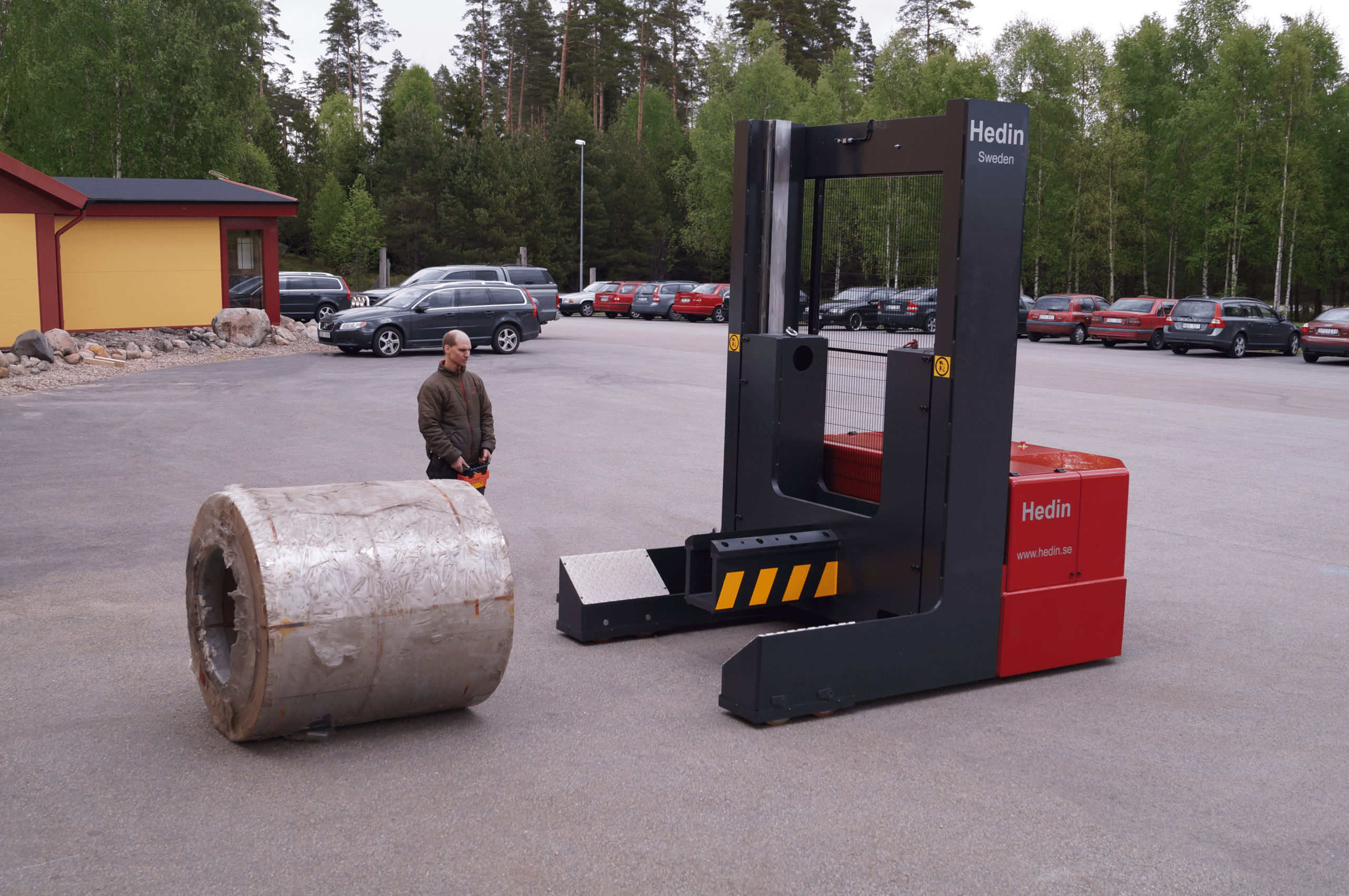

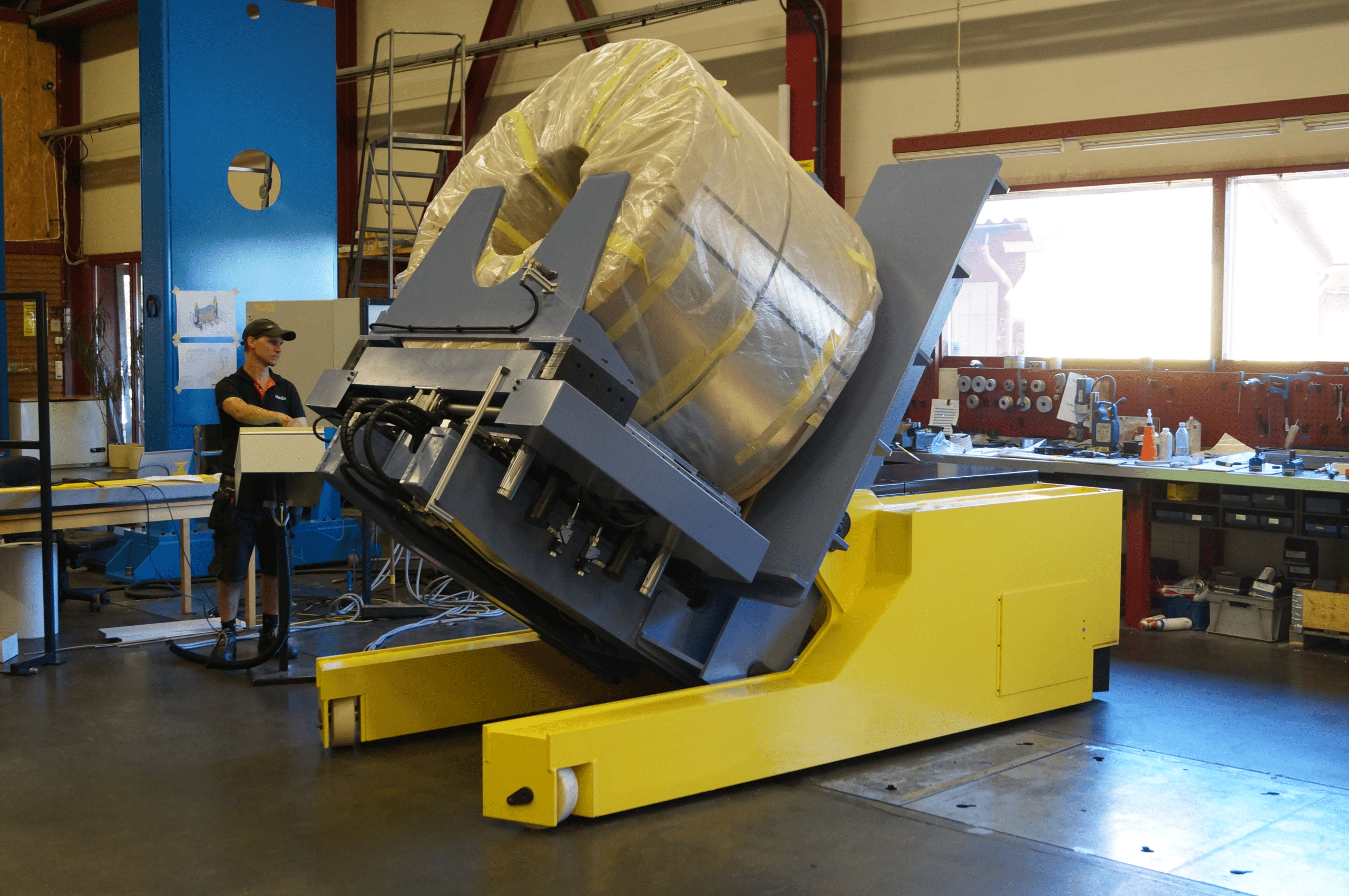

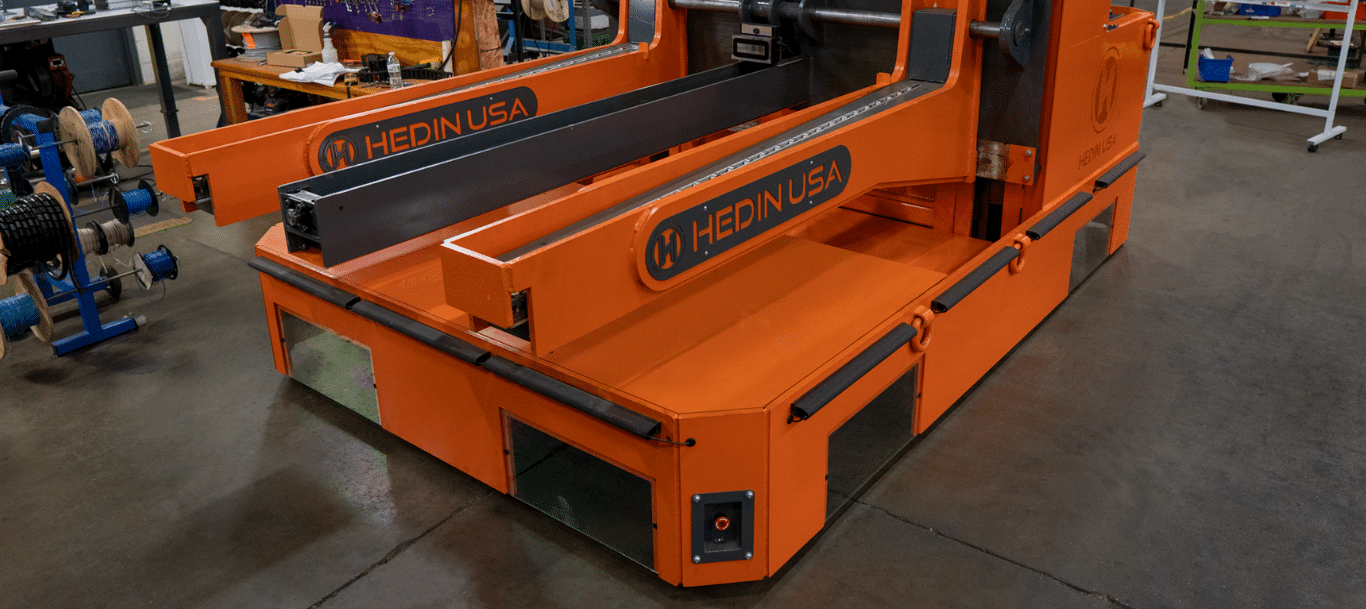

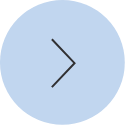

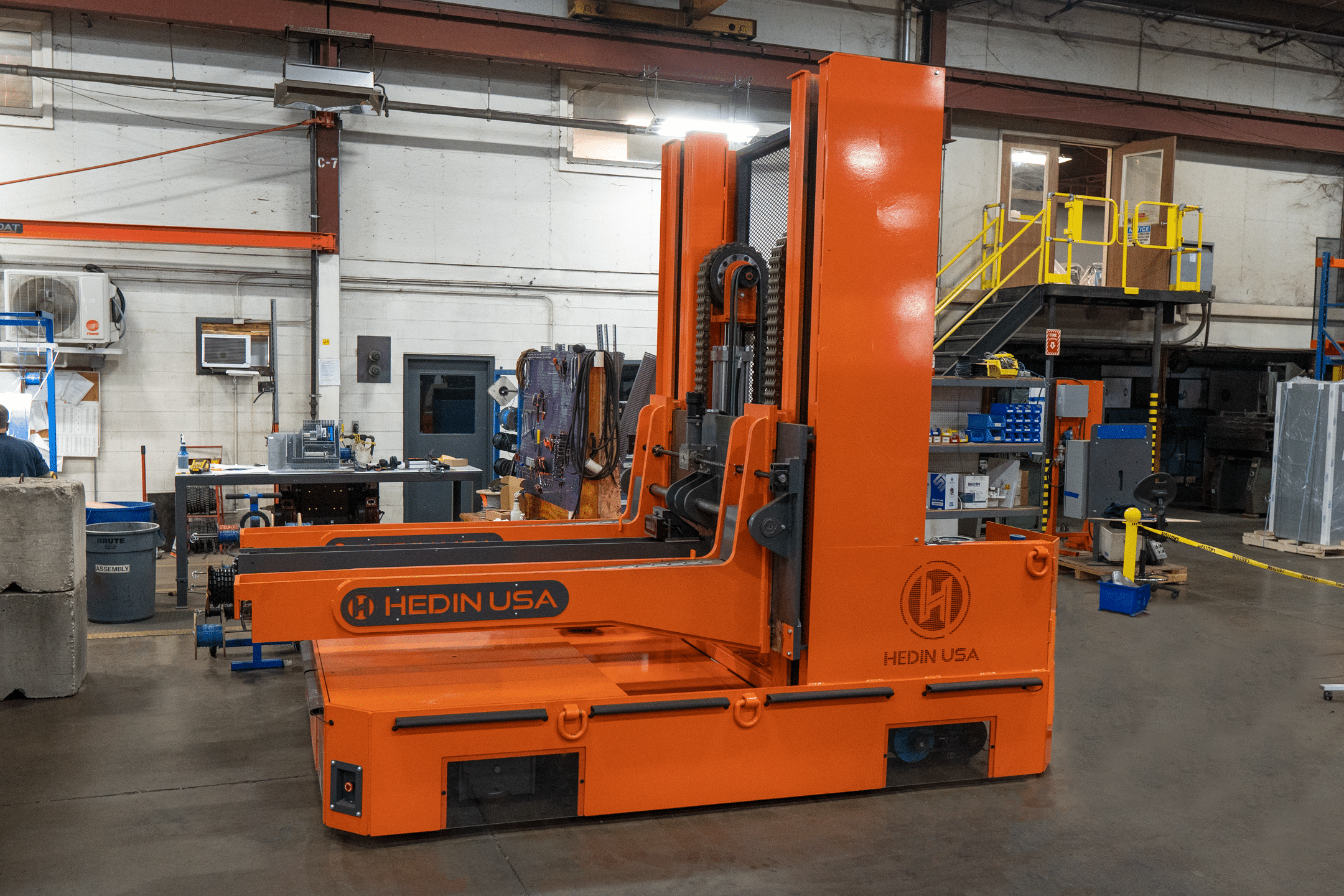

Fixed Drum & Reel Transporter

Quickly pick up and transport cable drums and reels; the Fixed Transporter uses fixed arms built to your drum size and capacity requirements. Hydraulic lifts within the arms pick up the drums from the ground.

+ Pick up loads right off the ground

+ Fixed arms, built to your requirements

+ Battery-powered Transporter

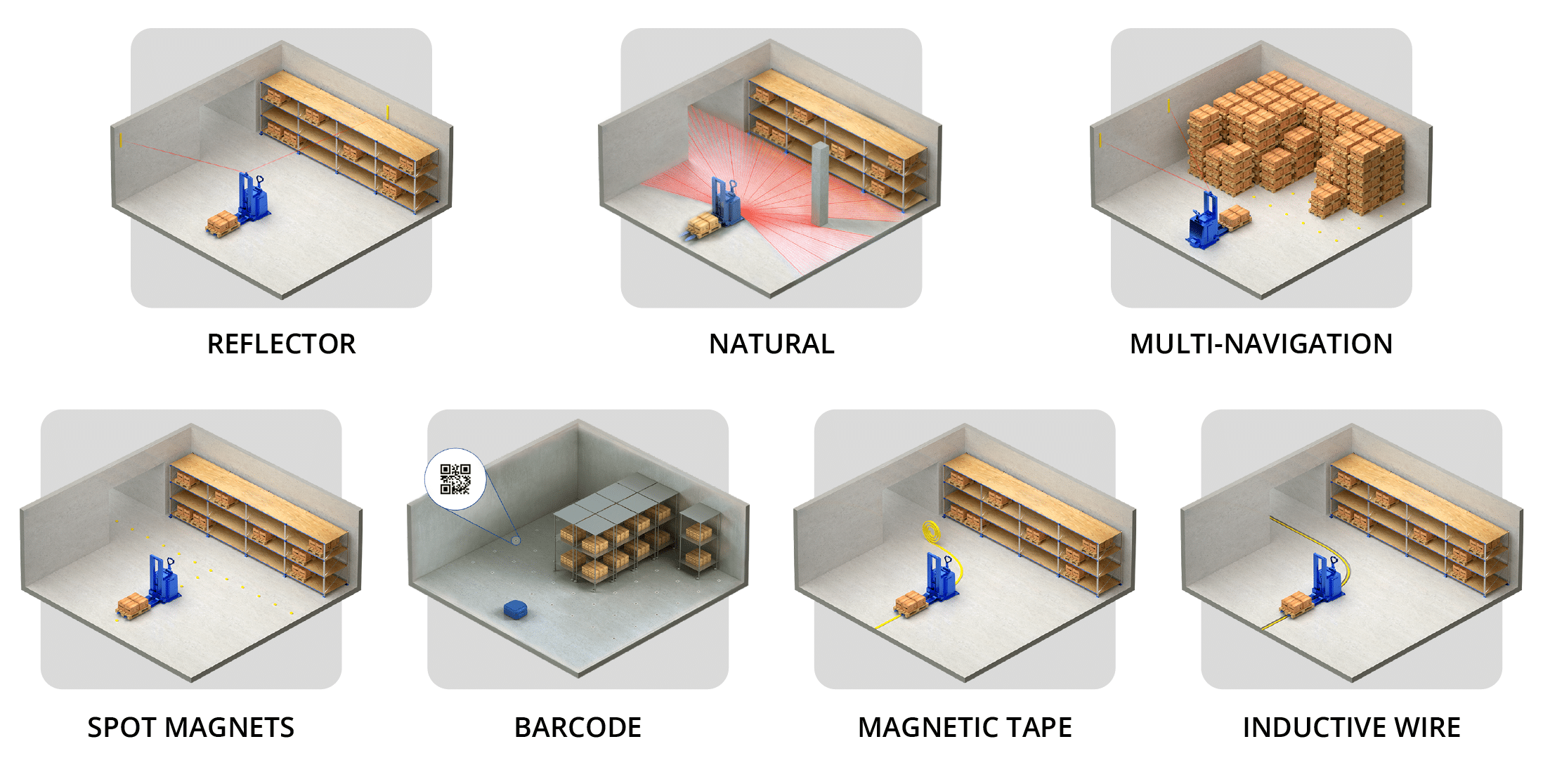

+ Automated AGV Compatible

+ Higher capacities compared to Adjustable Drum & Reel Transporter

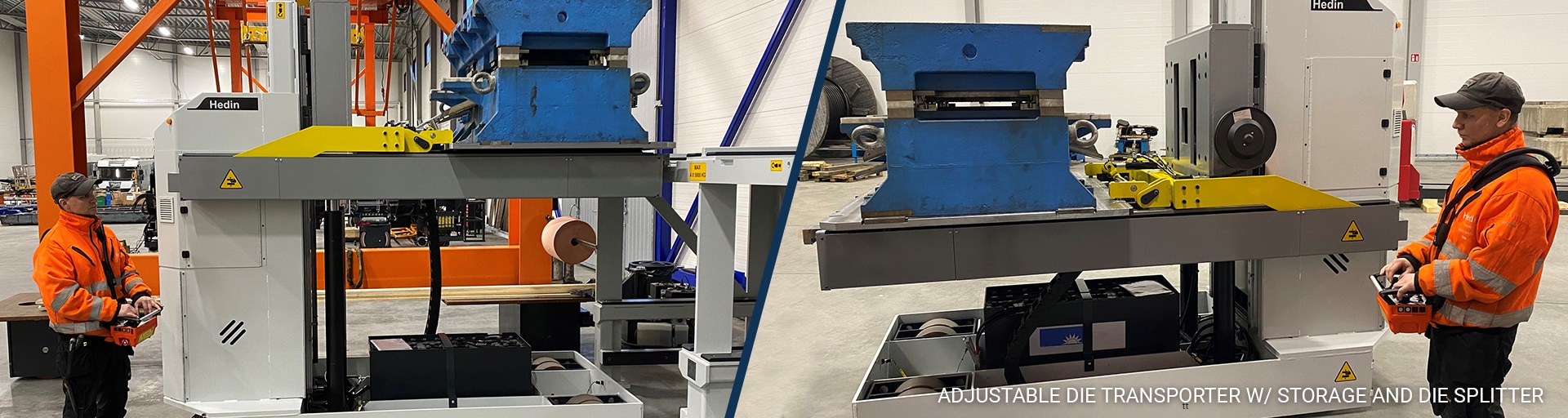

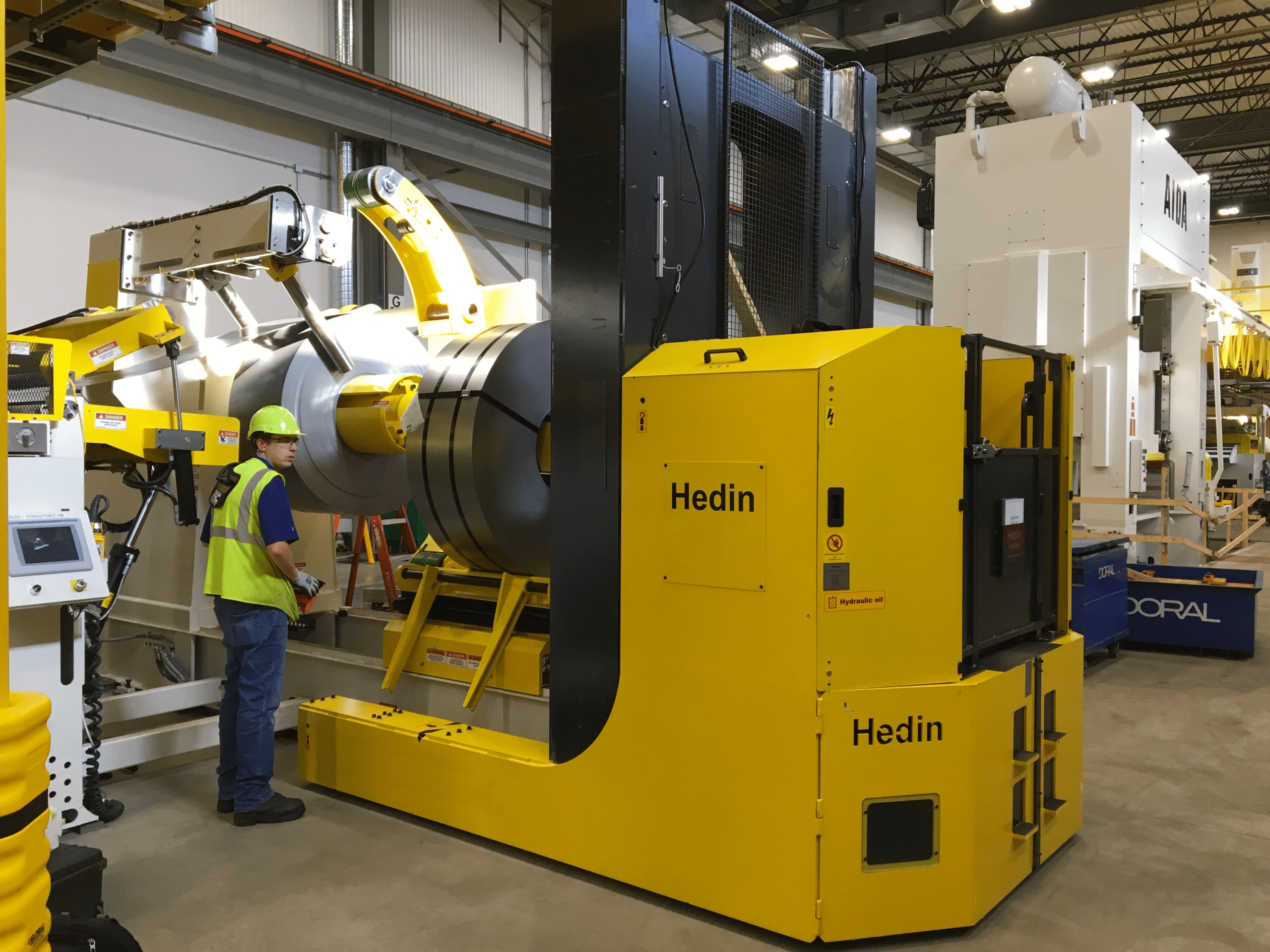

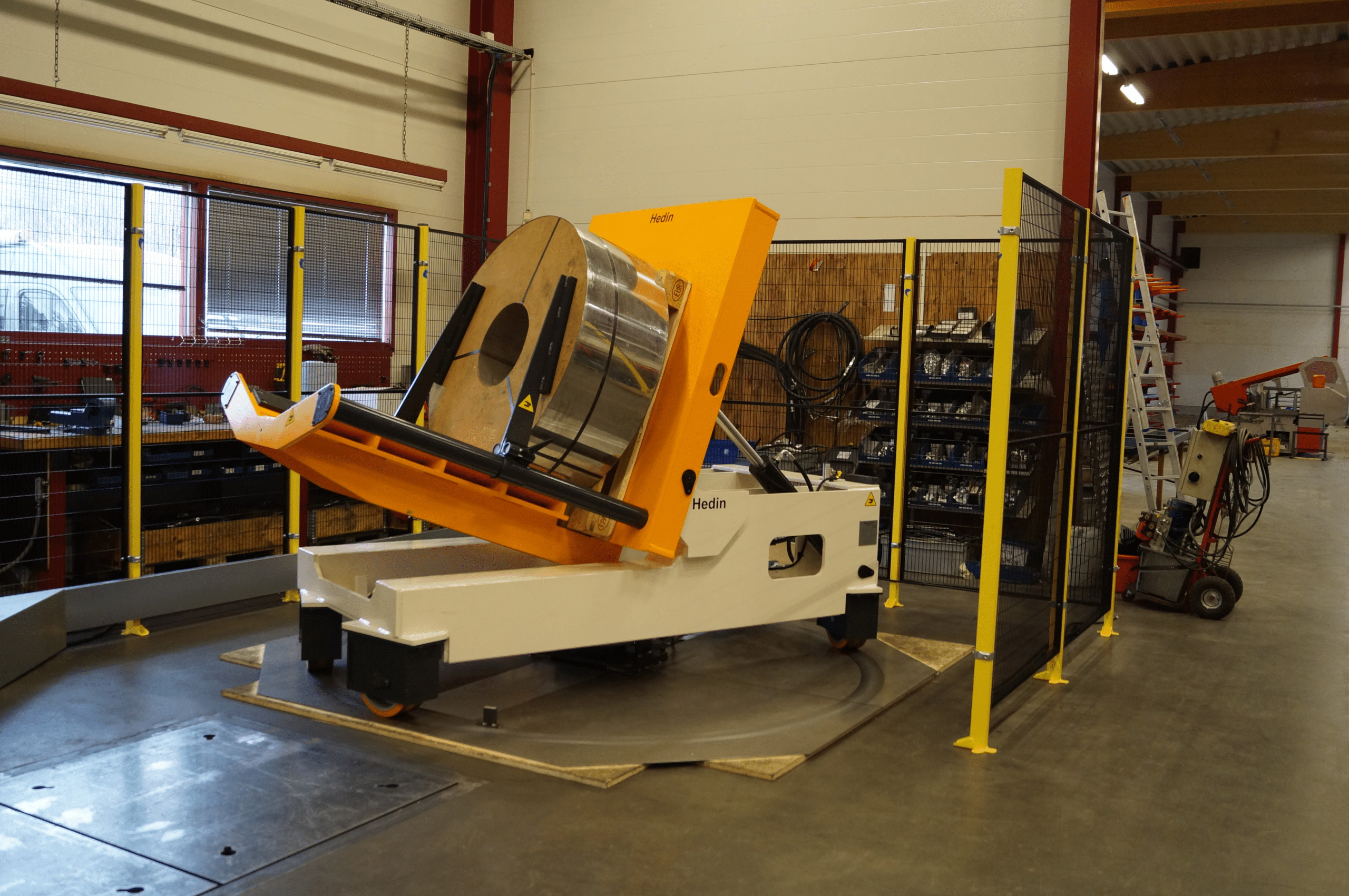

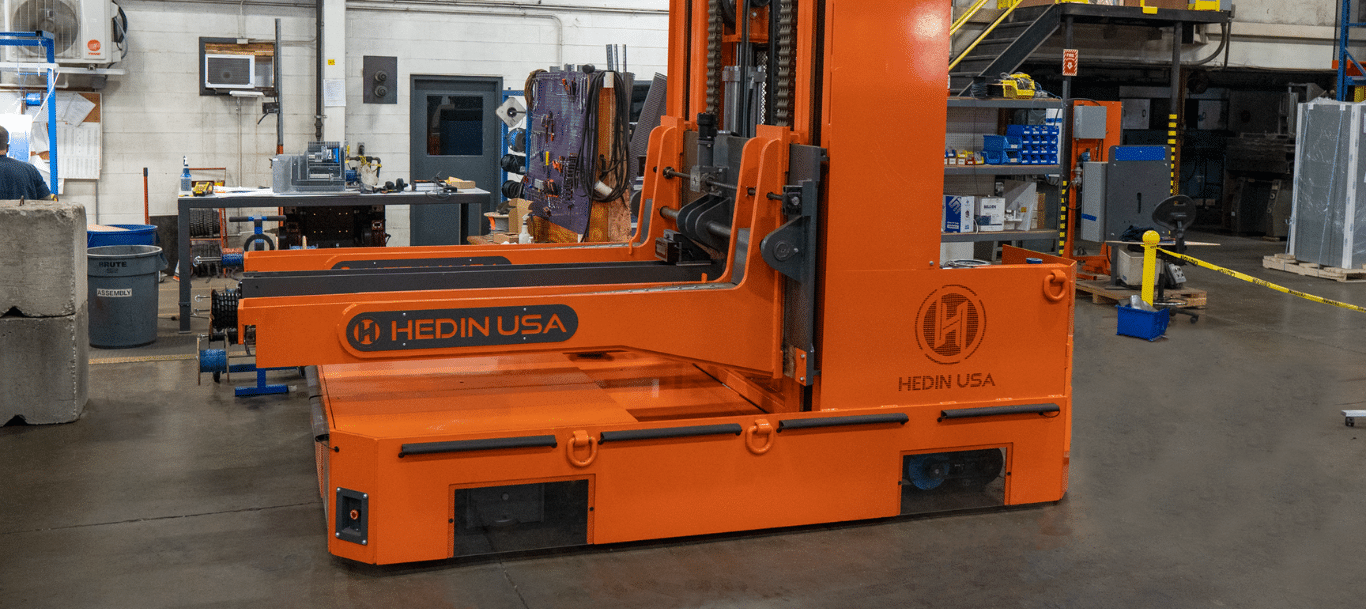

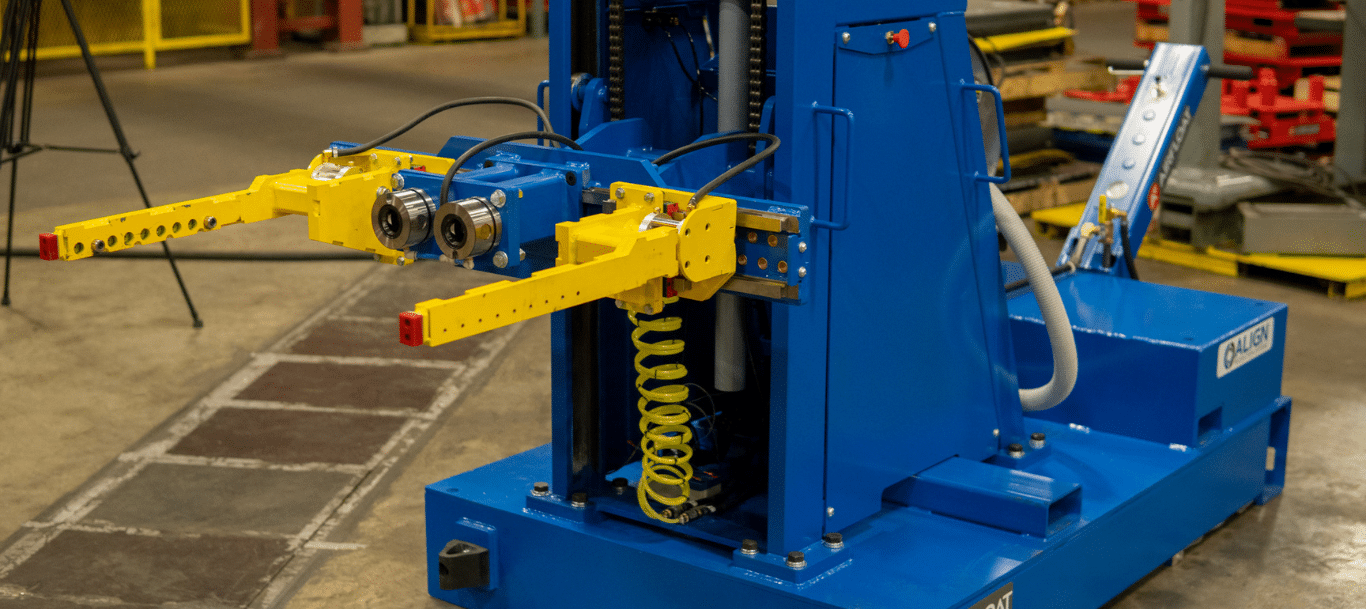

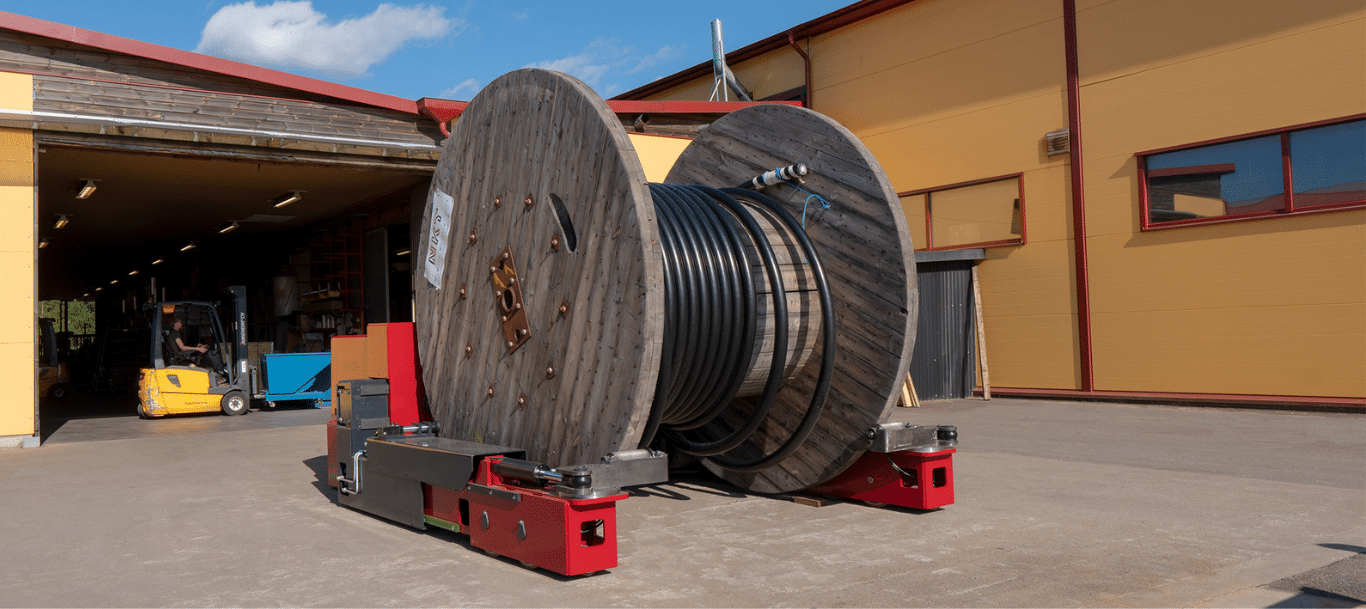

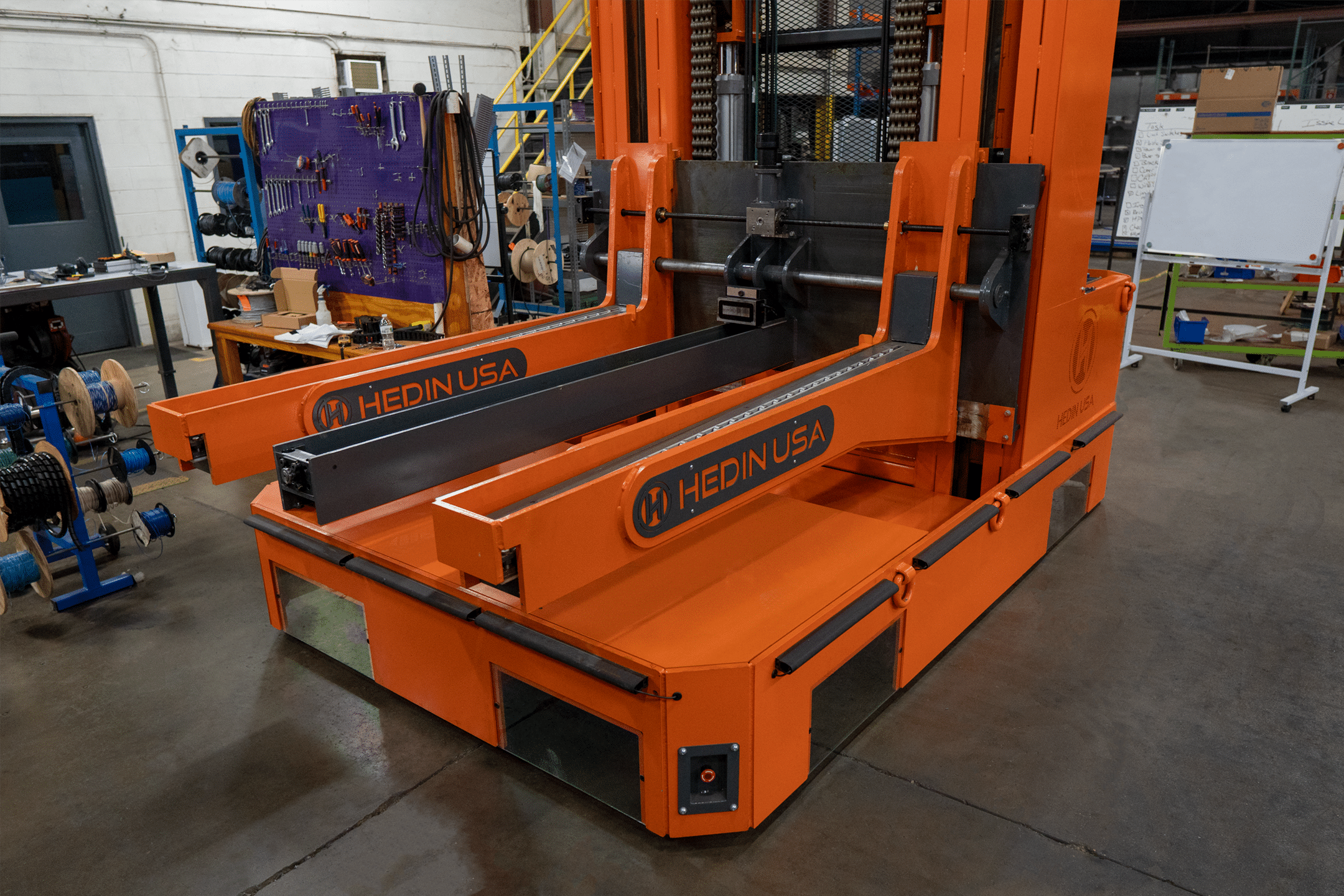

Are you working with different drum sizes? Our Adjustable Transporter can pick up a wide range of drum sizes right from the ground, with options for built-in rollers for spooling and unspooling the load.

+ Wide range of drum & reel sizes

+ Pick up loads right off the ground

+ Spooling & unspooling options

+ Battery-powered Transporter

+ Automated AGV Compatible

& Cable Handling!

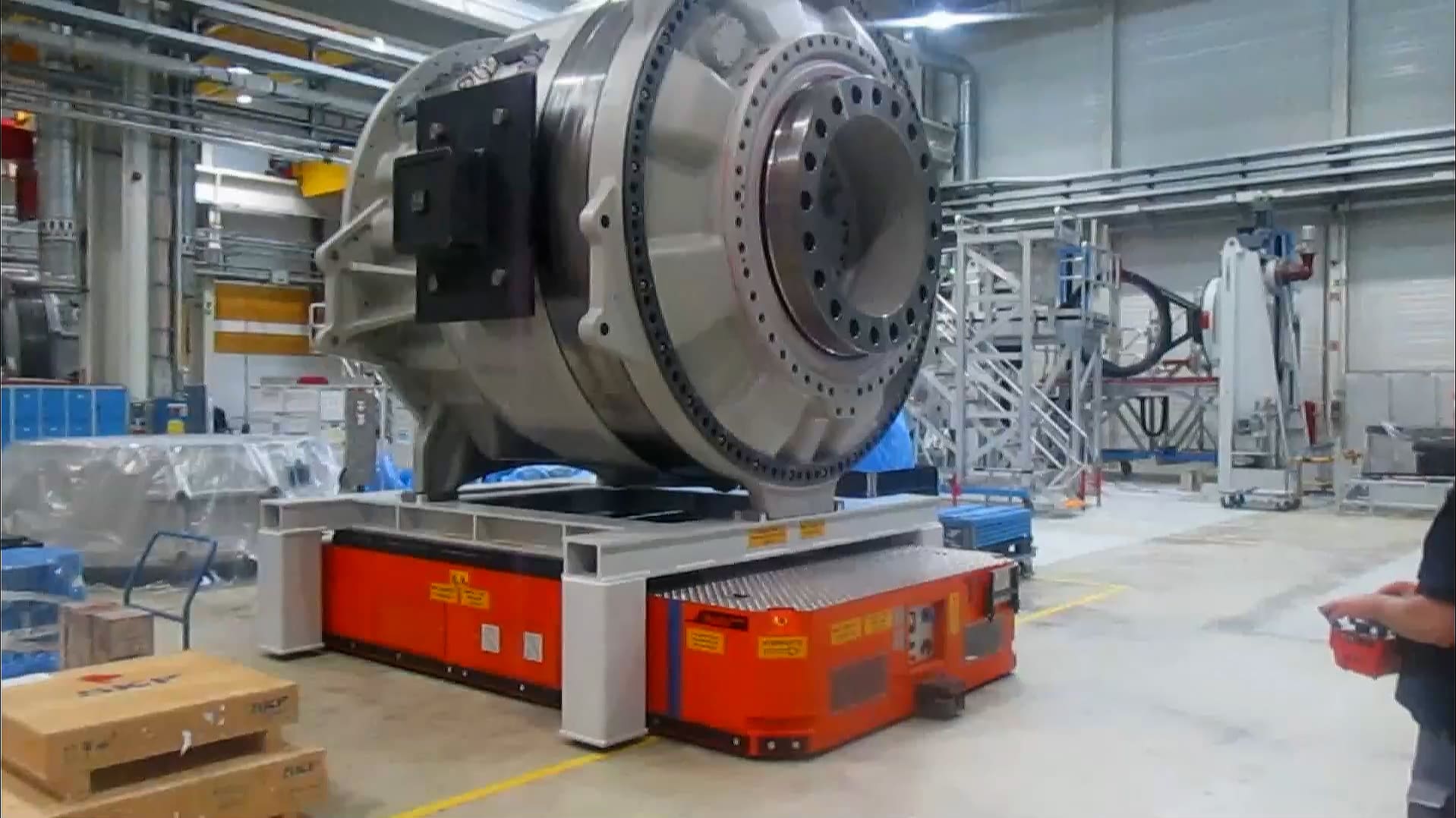

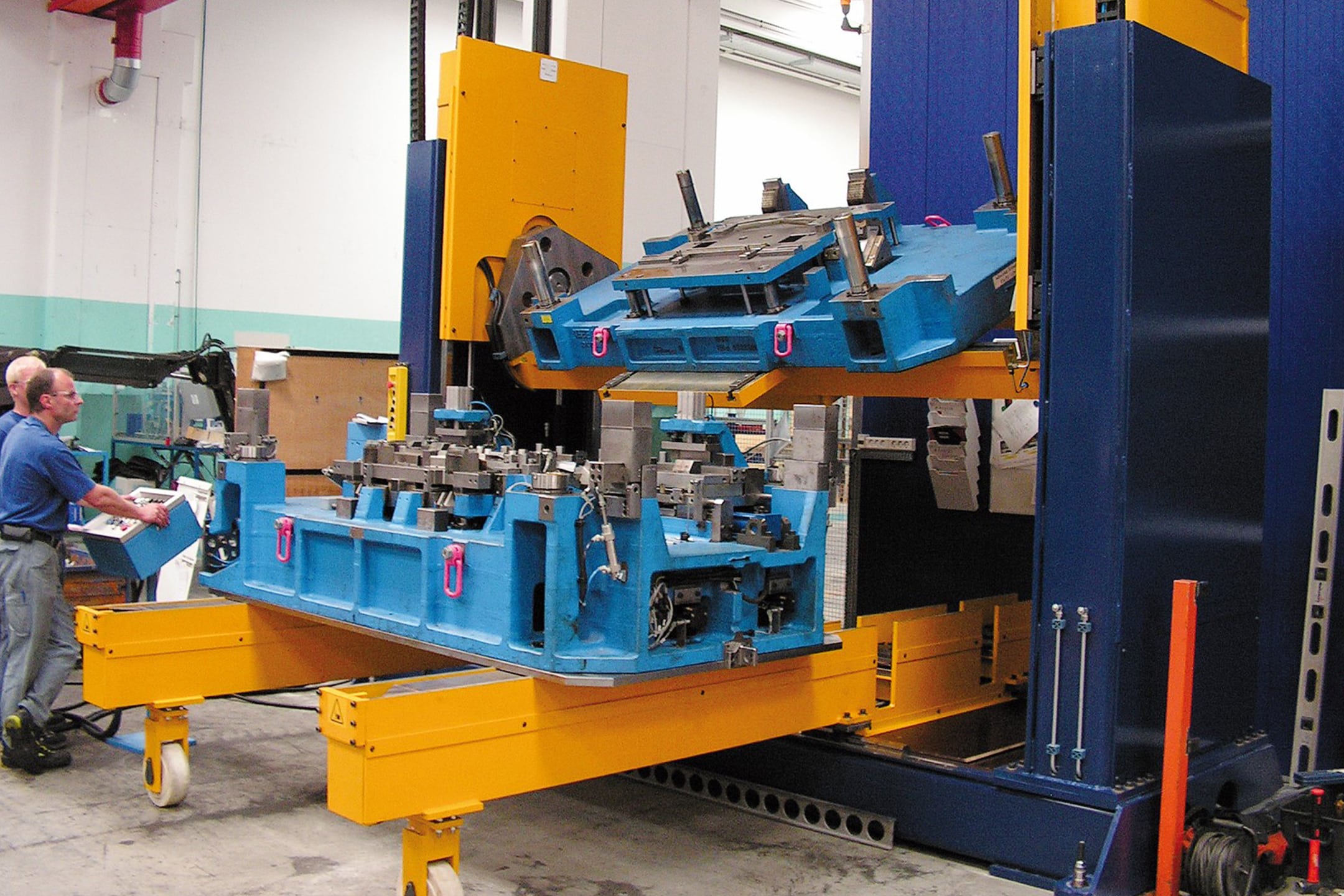

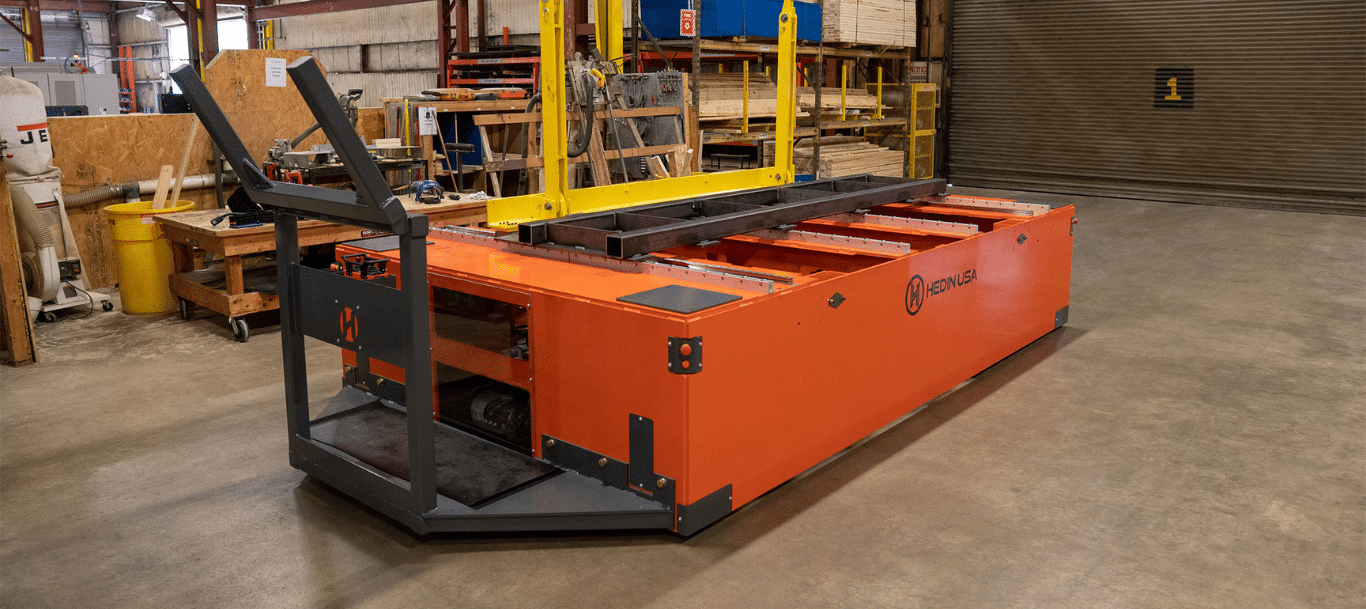

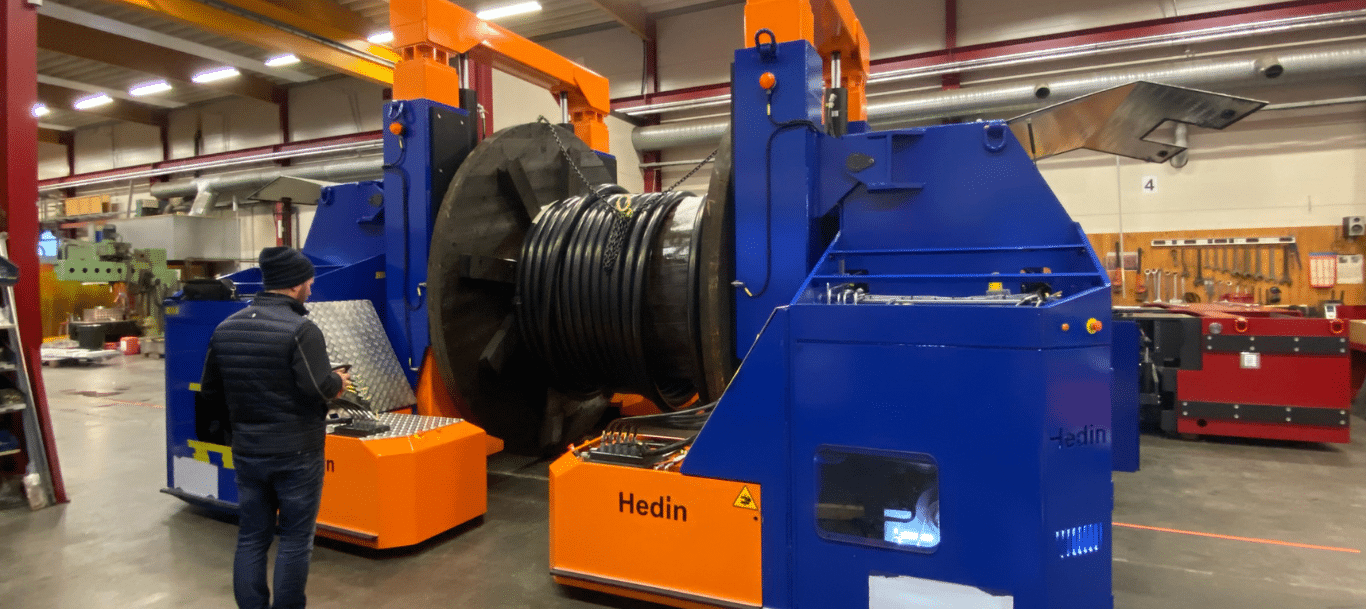

A flexible two-part system includes multiple low-cost carts and one or more battery Tuggers for moving loads – adding more carts and tuggers when needed. The carts can be designed and built to your specifications and load requirements with capacities over hundreds of thousands of pounds.

+ Low-cost carts & powerful tuggers

+ Easy interlocking push/pull hitch

+ Expand with manufacturing needs

+ Battery-powered Transporter

+ Safe, single-operator operation

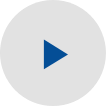

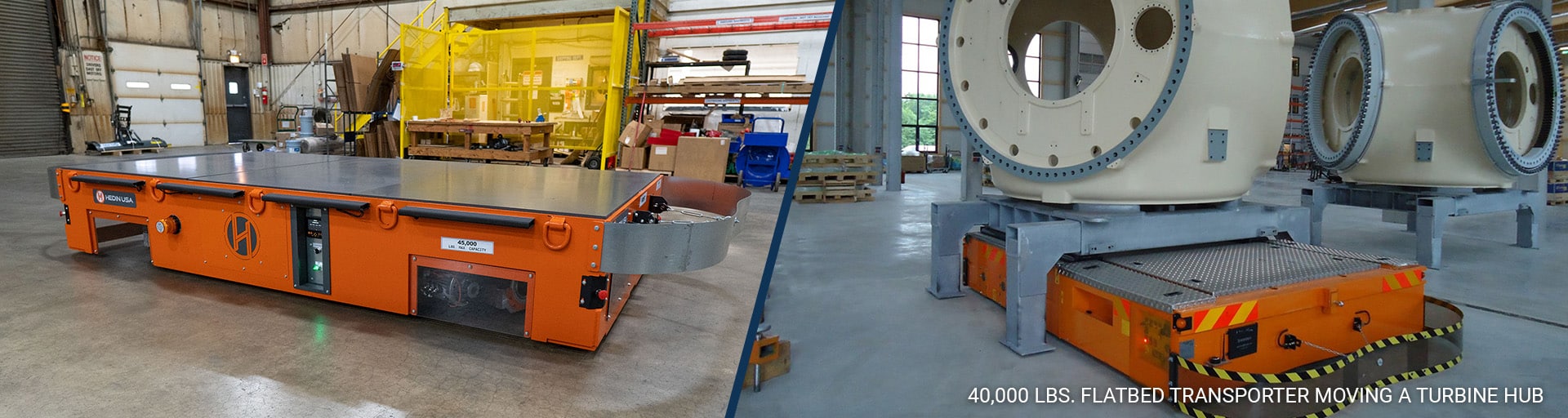

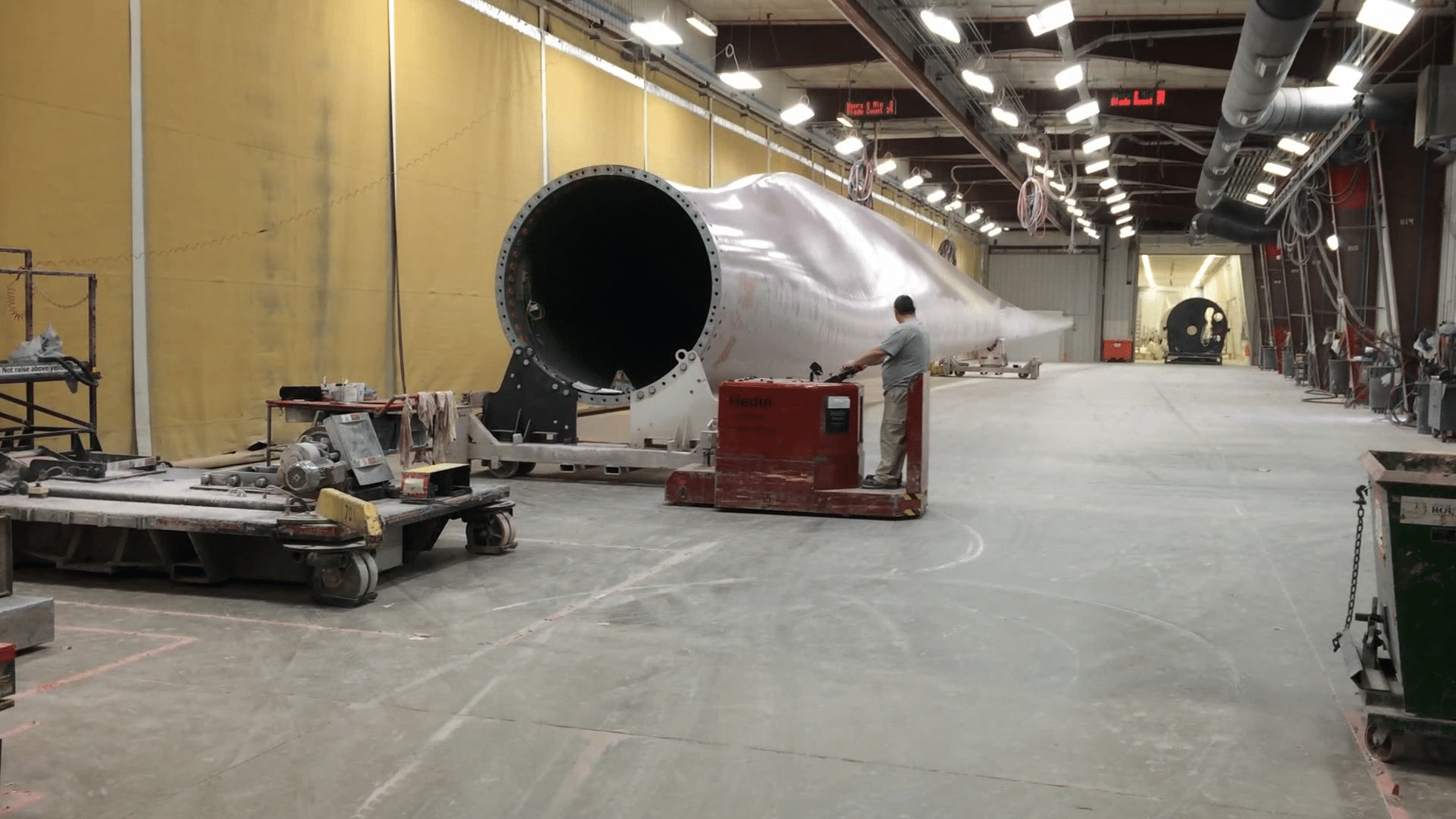

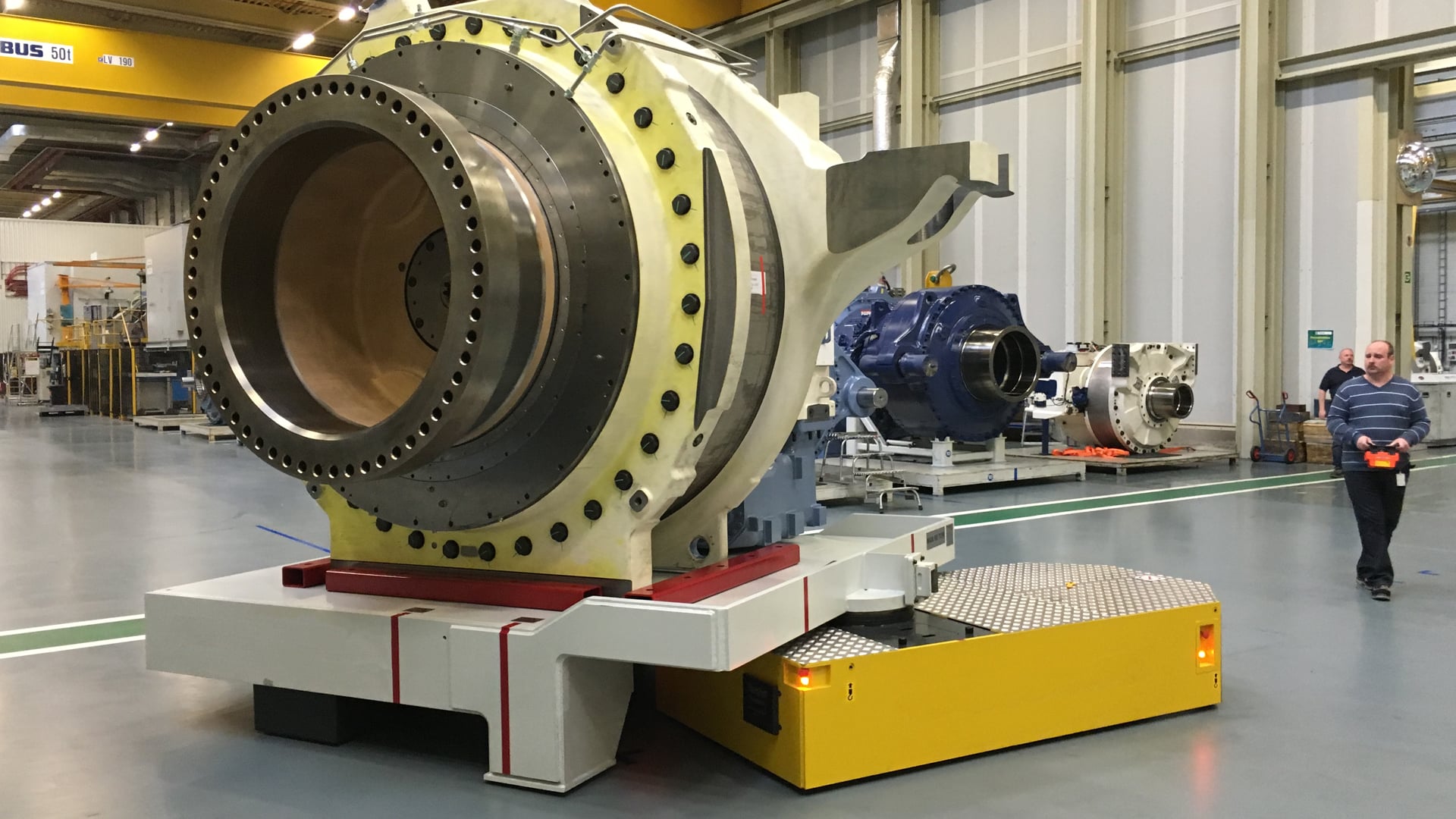

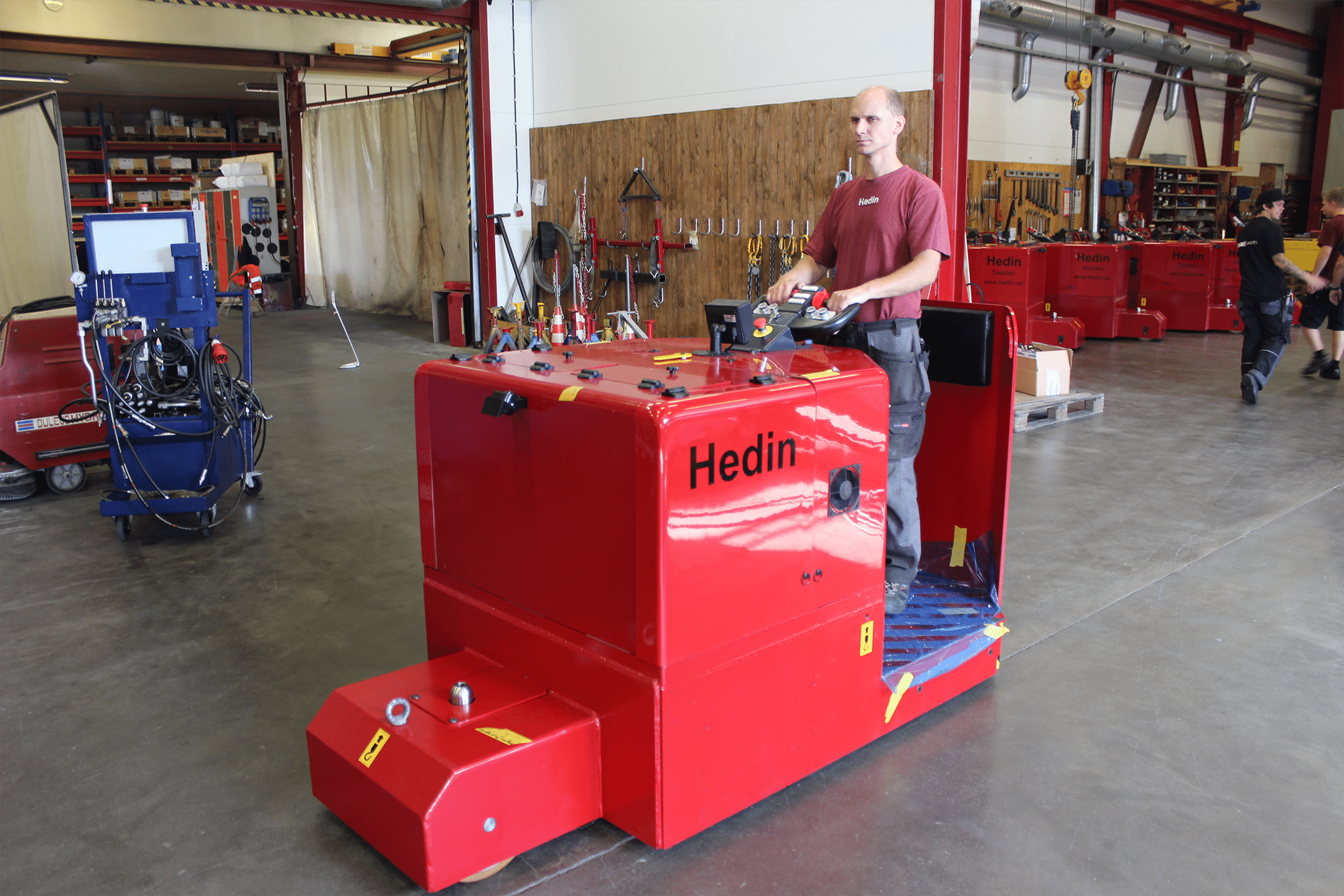

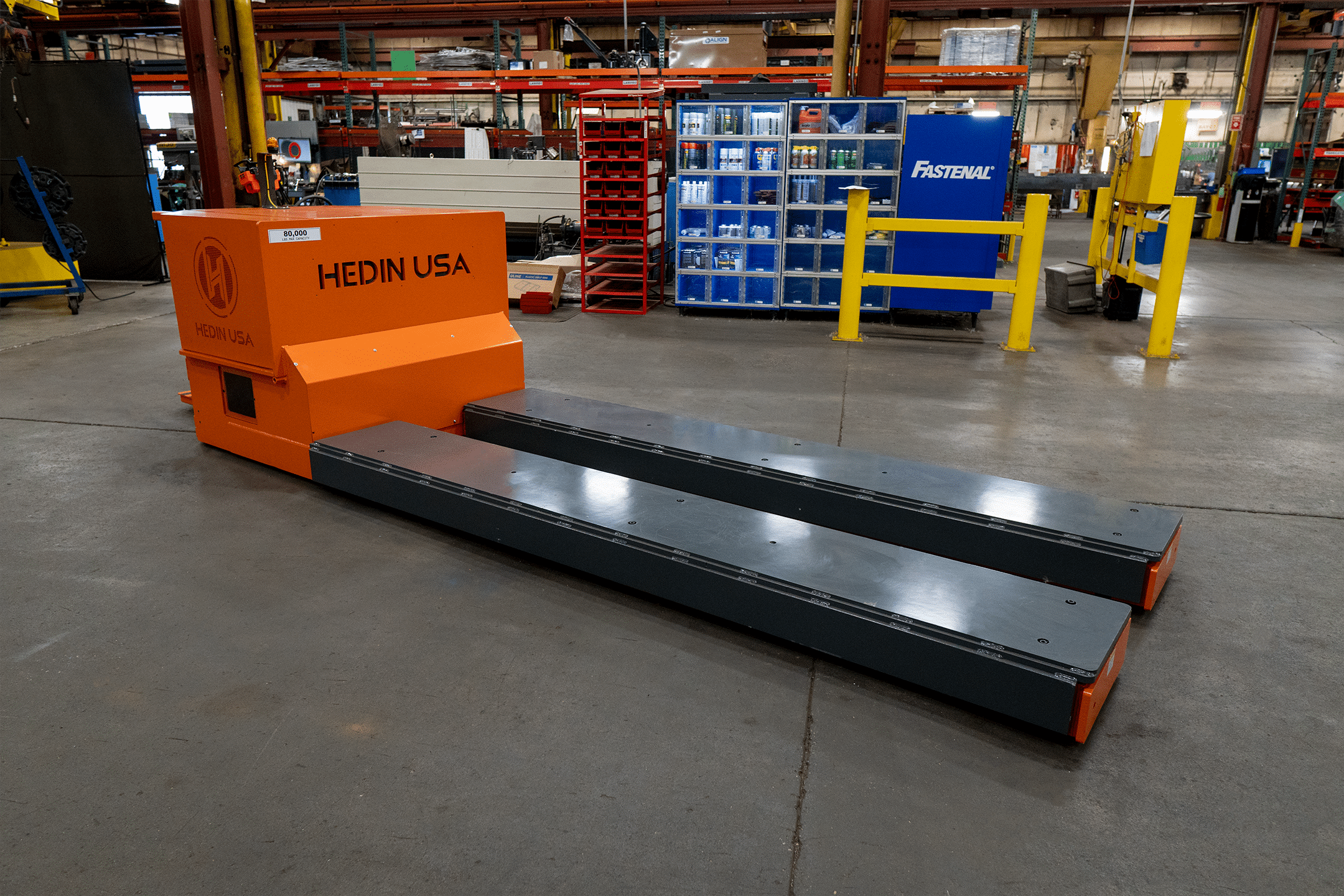

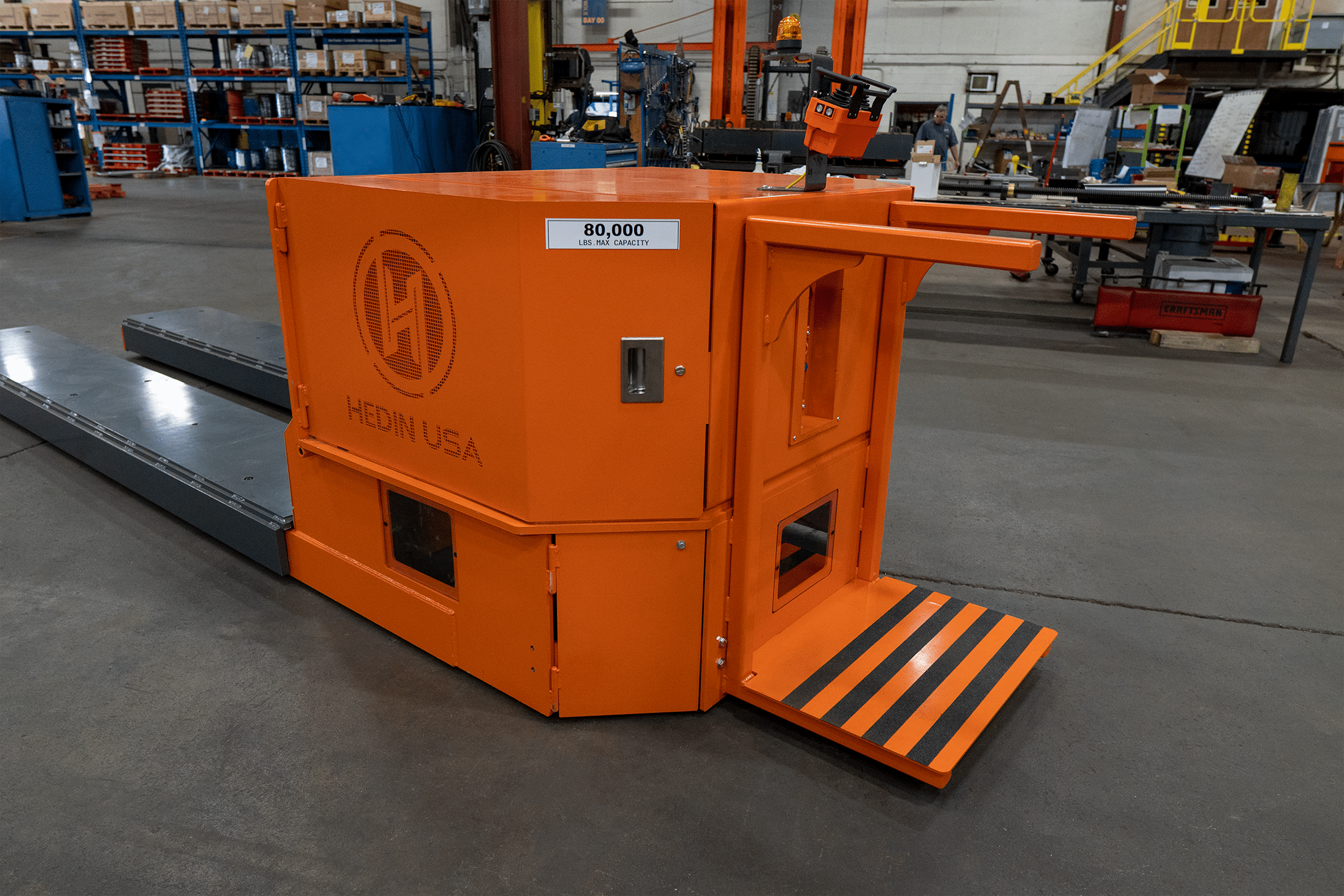

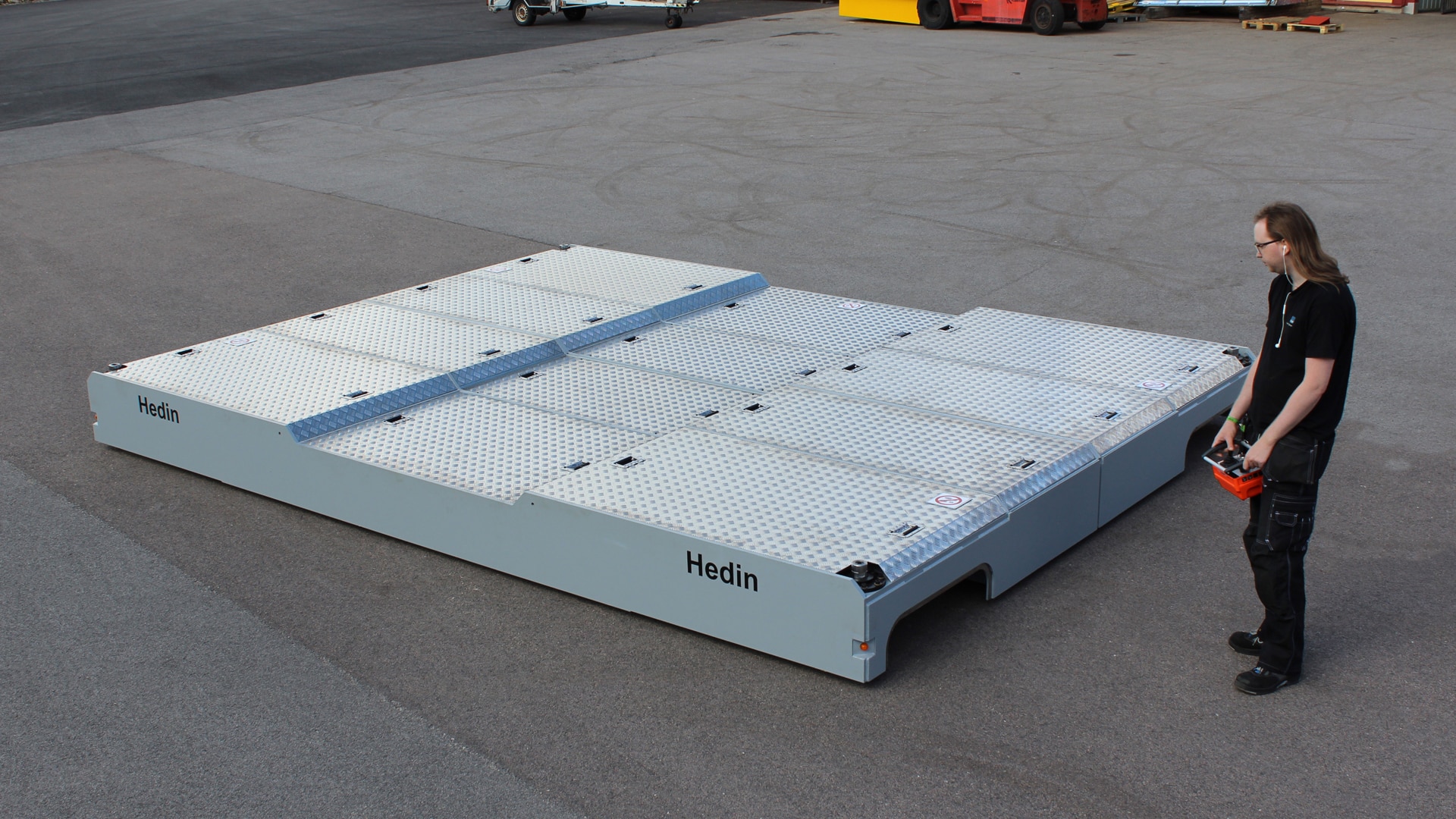

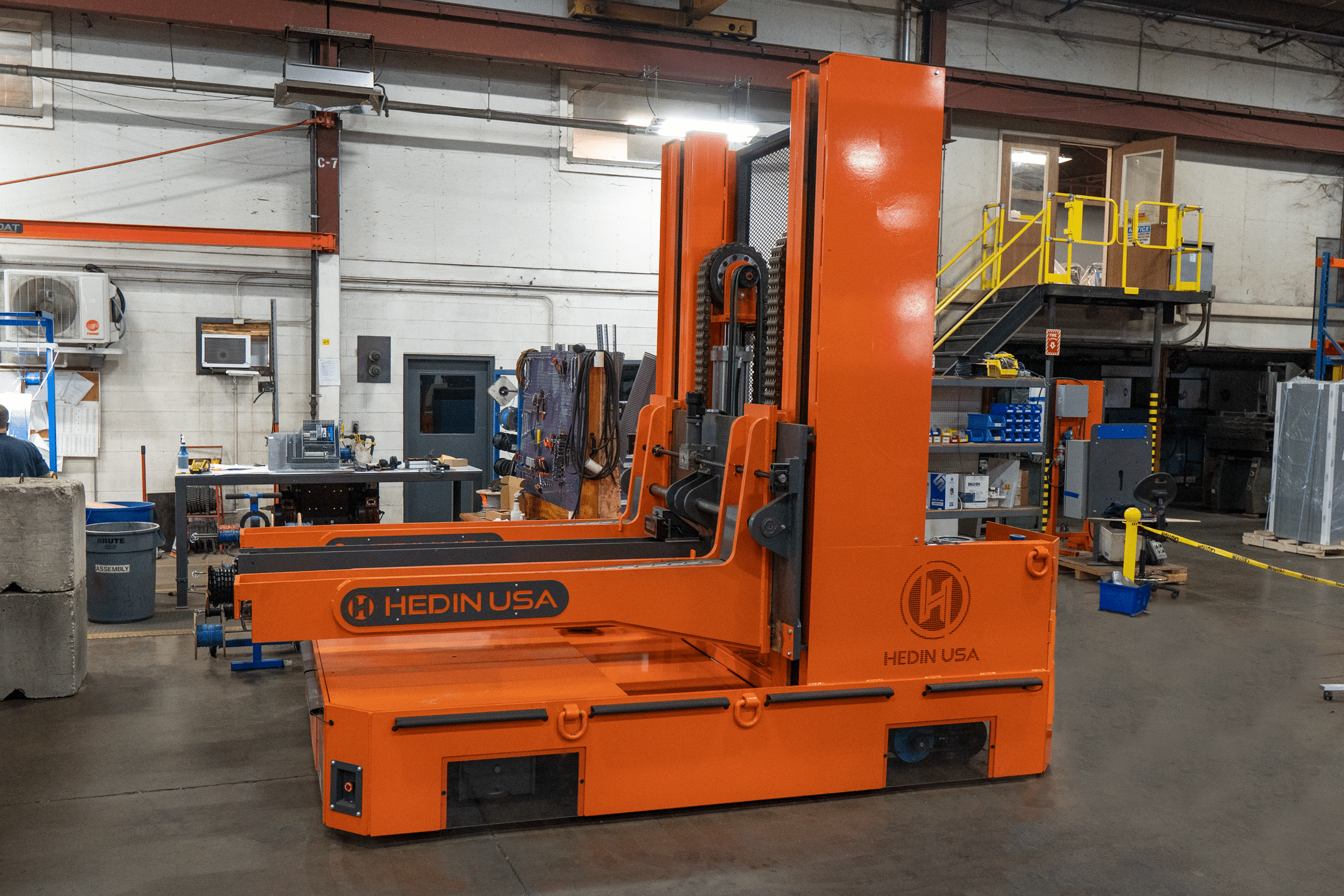

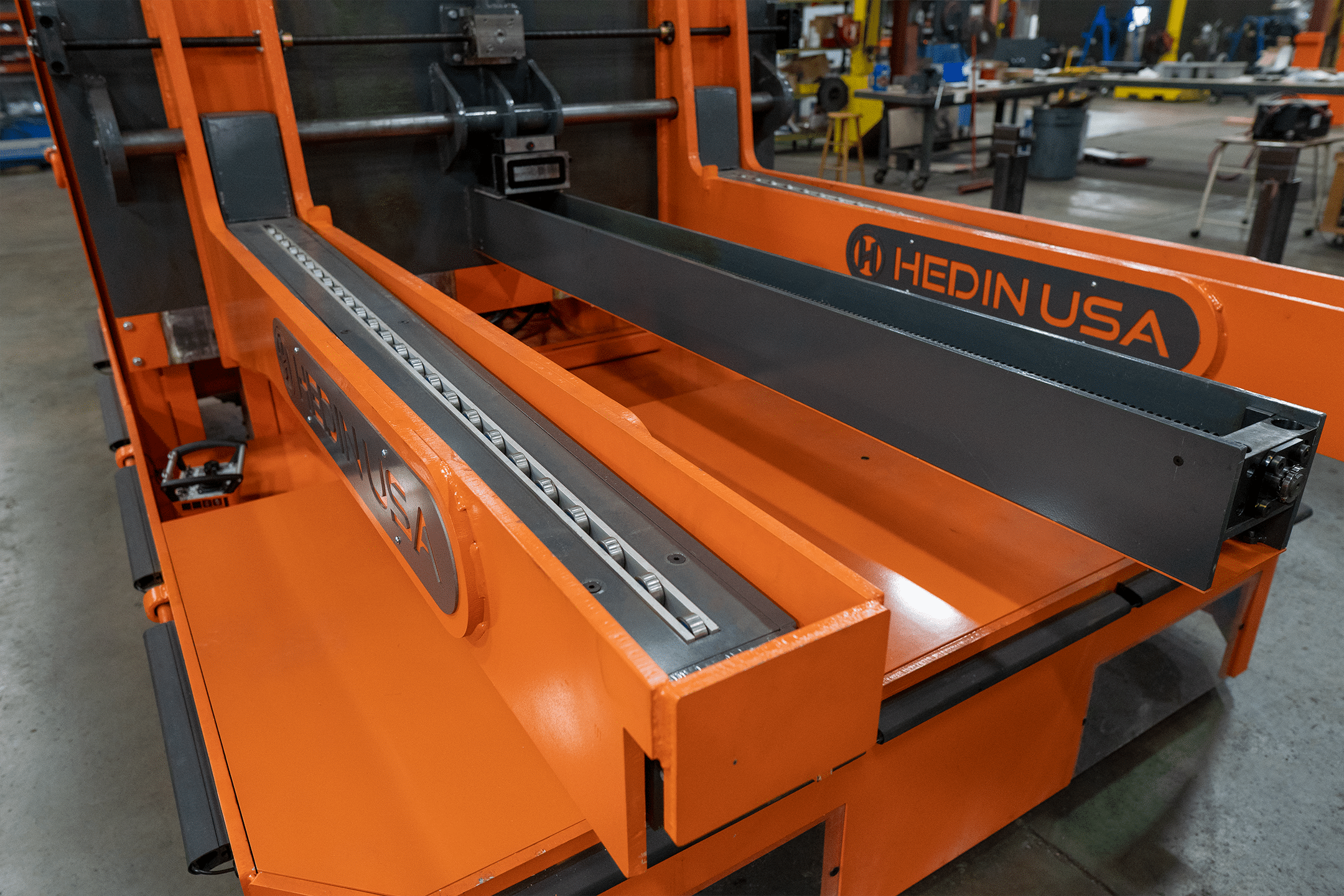

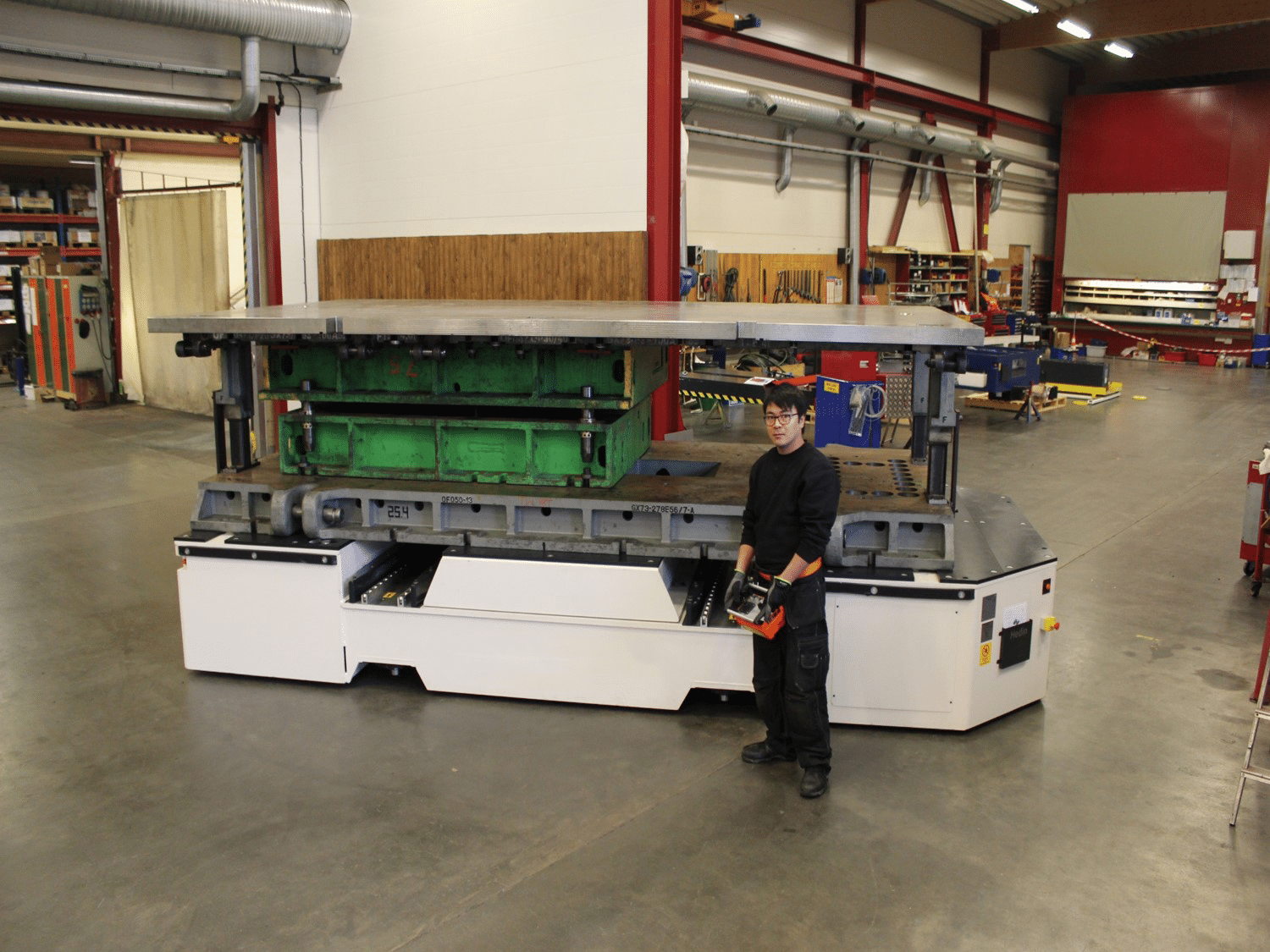

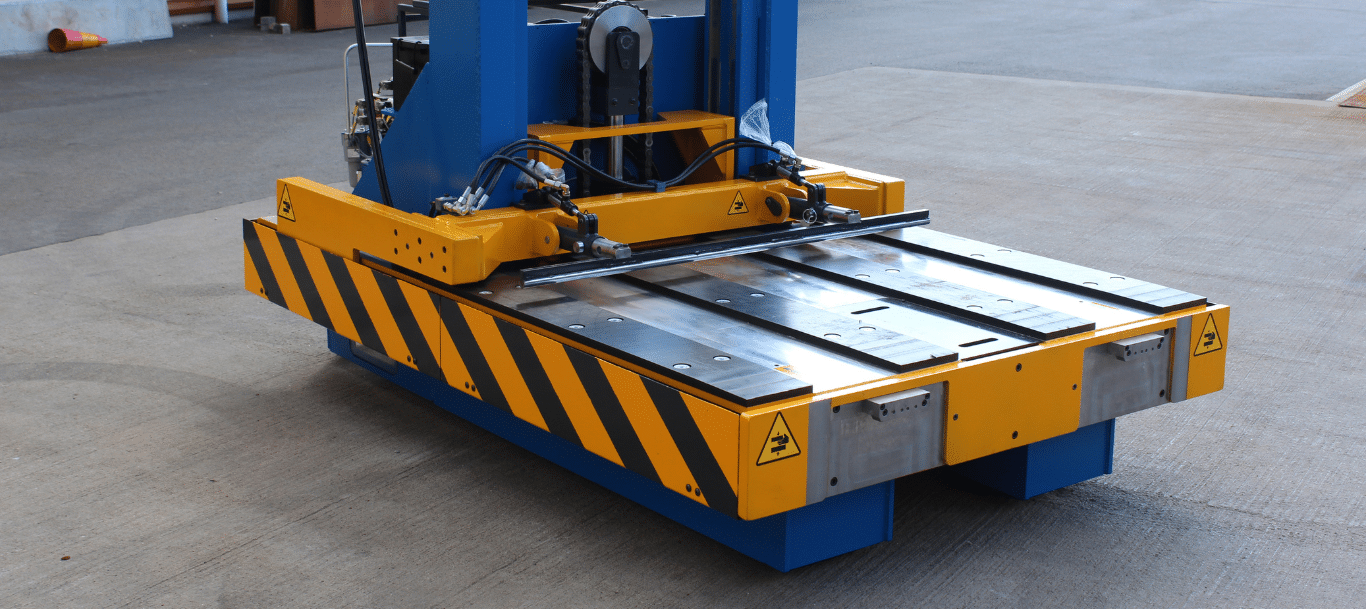

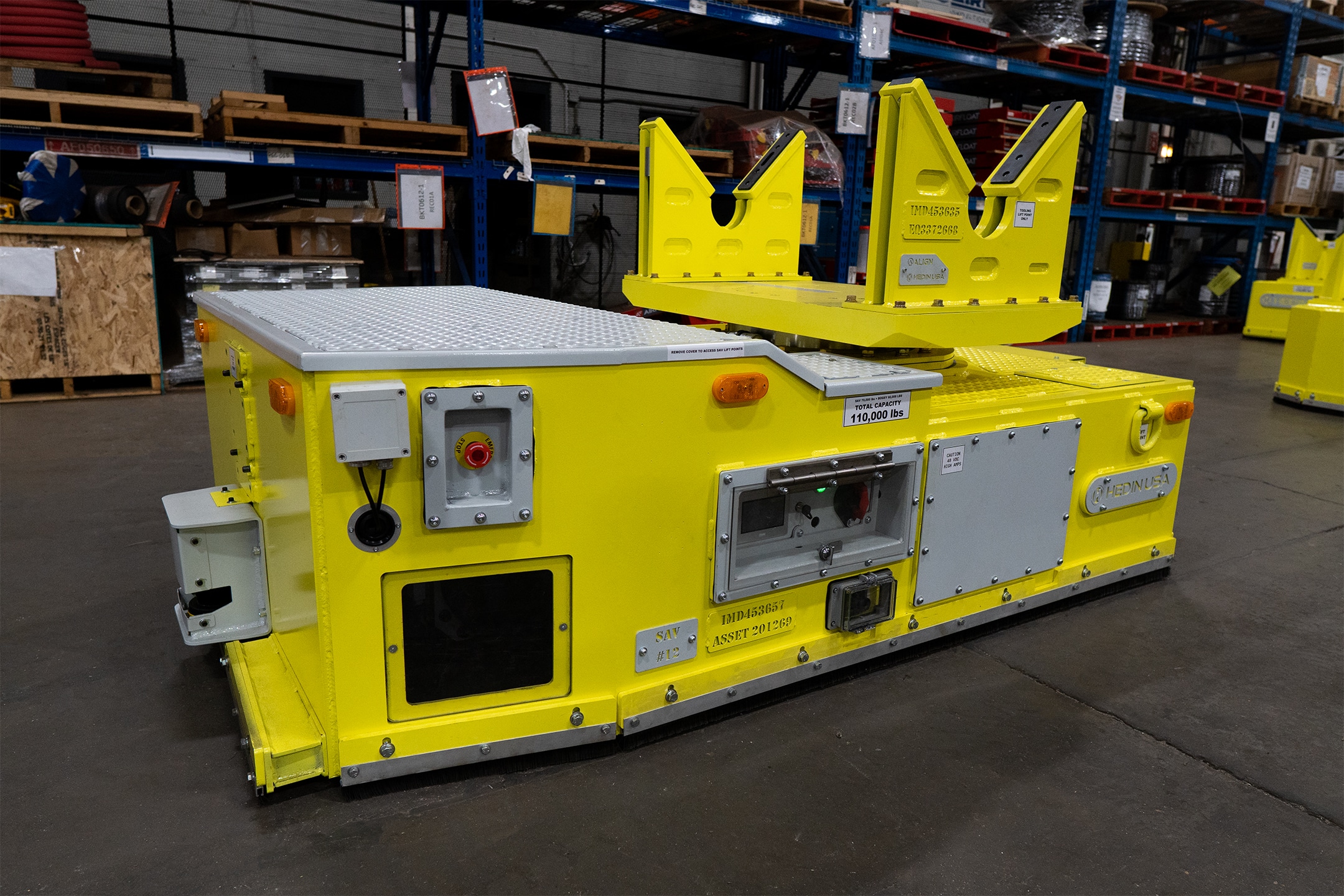

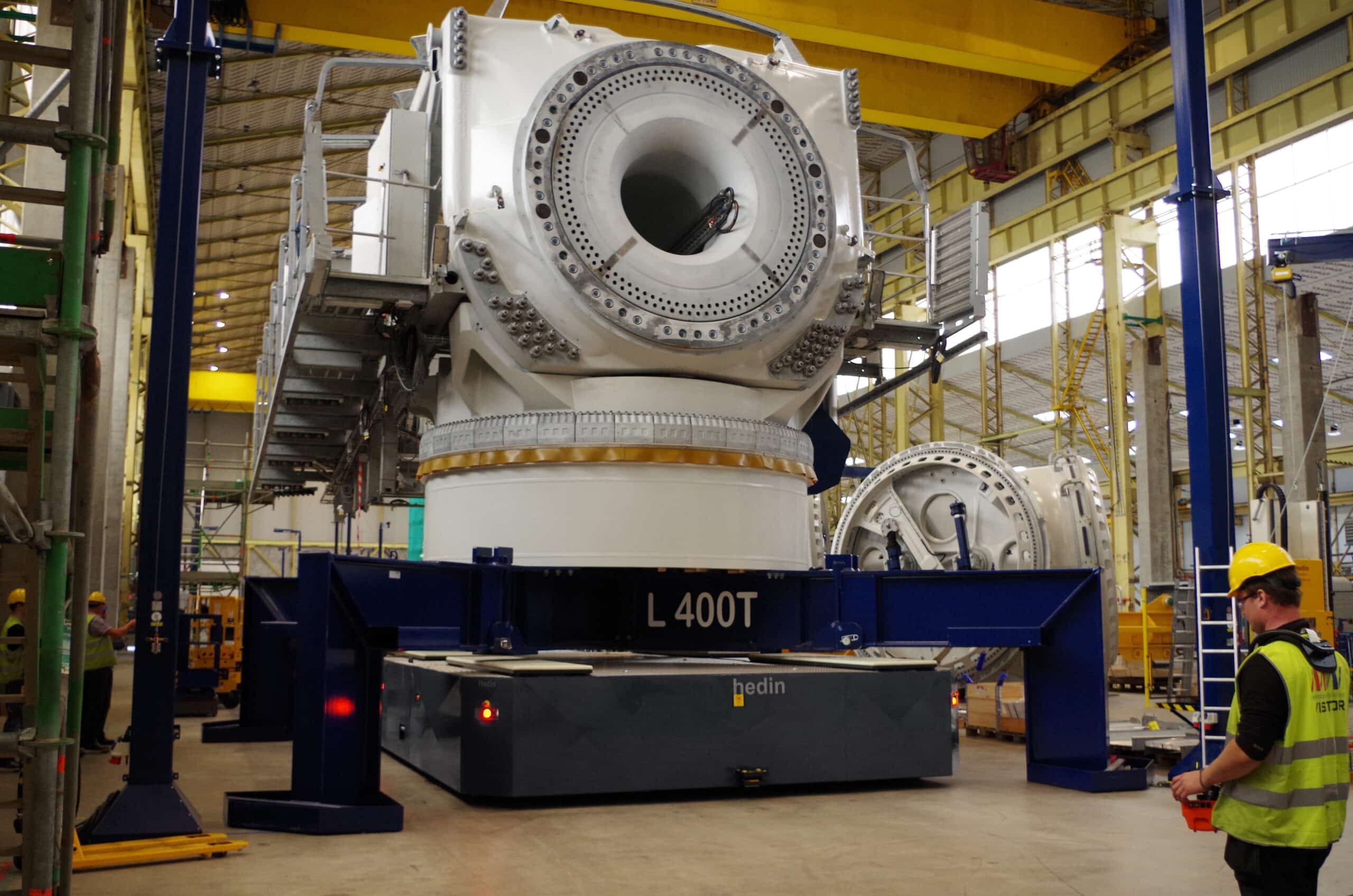

No load is too heavy; our Flatbed Transporters handle various sizes and capacities, with custom capacities of over a million pounds. A single operator can move the load effortlessly while maintaining positive control.

+ Extremely high capacities

+ Directly with the load or pallet

+ Battery-powered Transporter

+ Automated AGV Compatible

PROUD MEMBER OF

Back to Wire, Wire Rope, & Cable Solutions

Back to Wire, Wire Rope, & Cable Solutions