High Capacity Turntables: Keeping Your Line Moving

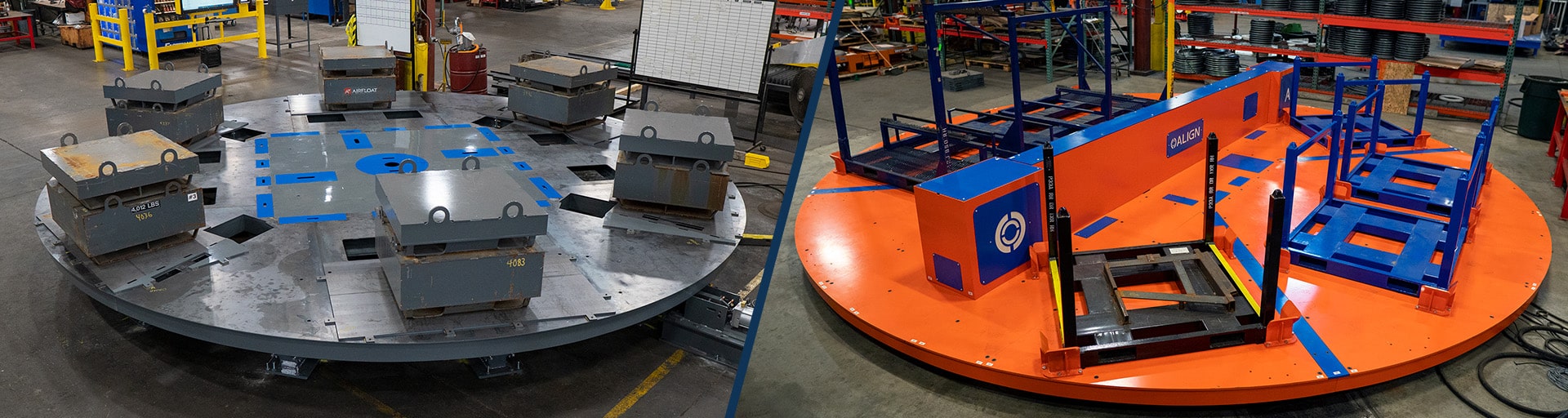

mechanical and air caster turntables

Understanding Turntables

Turntables are utilized in various industrial settings because they offer a flexible solution for handling and positioning heavy loads. They are commonly used with forklifts and robots to streamline end-of-line handling and prevent bottlenecks. In this article, we will explore the two types of turntables offered by Align Production Systems: mechanical and air caster turntables. By understanding these options, you can make an informed decision about which turntable is best for your operational needs.

Features of Mechanical Turntables:

Mechanical turntables are designed with heavy duty construction, built from durable materials to ensure longevity and resistance to wear and tear. They have a high load capacity, supporting weights ranging from a few hundred pounds to several tons, which makes them ideal for heavy-duty applications. The turntables can be customized with different top configurations including round and square tops, or other customizations to handle various load shapes and sizes.

Use Cases for Mechanical Turntables:

- Assembly Lines: Ideal for positioning parts for assembly tasks.

- Welding Stations: Facilitates the rotation of parts for welding.

- Inspection and Testing: Used for inspection by rotating components to different angles.

- Painting and Coating: Rotate the part to ensure that the entire object is painted.

- Manufacturing and Fabrication: Positions heavy parts for machining, cutting, or drilling.

Features of Air Caster Turntables:

Air caster turntables offer frictionless movement by utilizing air bearings for smooth rotation, making them ideal for positioning and handling of heavy loads. These turntables feature customizable tops, available in both round and square configurations, and boast a robust load capacity, enabling them to handle substantial weights with ease.

Use Cases for Air Caster Turntables:

- Aerospace Manufacturing: Delicate handling of large components.

- Electronics Manufacturing: Precise positioning for assembly and testing.

- Automotive Industry: Smooth rotation for parts assembly and inspection.

- Metal Stamping Industry: For moving stamped parts to racking system.

Conclusion

Selecting the right turntable for your application involves understanding the different types available and their respective use cases. Whether you need a mechanical, air caster, standard, pit-mounted, or high-speed turntable, Align Production Systems provides reliable and efficient solutions tailored to your needs. By choosing the right turntable, you can enhance productivity, ensure safety, and streamline operations in your industrial setting.