|

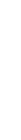

Model No.

Model No.

AX050-0288

AX050-0288

|

Capacity (lbs)

Capacity (kgs)

100,000

45,359

|

Base Diameter (in)

Base Diameter (mm)

288

7,315

|

Top Diameter Min (in)

Top Diameter Min (mm)

288

7,315

|

Top Diameter Max (in)

Top Diameter Max (mm)

324

8,230

|

Caster Diameter (in)

Caster Diameter (mm)

36

914

|

Height (in)

Height (mm)

13

330

|

Air Flow (scfm)

Air Flow (l/m)

138

3908

|

|

Model No.

Model No.

AX050-0252

AX050-0252

|

Capacity (lbs)

Capacity (kgs)

100,000

45,359

|

Base Diameter (in)

Base Diameter (mm)

252

6,401

|

Top Diameter Min (in)

Top Diameter Min (mm)

252

6,401

|

Top Diameter Max (in)

Top Diameter Max (mm)

288

7,315

|

Caster Diameter (in)

Caster Diameter (mm)

36

914

|

Height (in)

Height (mm)

13

330

|

Air Flow (scfm)

Air Flow (l/m)

138

3908

|

|

Model No.

Model No.

AX050-0216

AX050-0216

|

Capacity (lbs)

Capacity (kgs)

100,000

45,359

|

Base Diameter (in)

Base Diameter (mm)

216

5,486

|

Top Diameter Min (in)

Top Diameter Min (mm)

216

5,486

|

Top Diameter Max (in)

Top Diameter Max (mm)

252

6,401

|

Caster Diameter (in)

Caster Diameter (mm)

30

762

|

Height (in)

Height (mm)

13

330

|

Air Flow (scfm)

Air Flow (l/m)

114

3228

|

|

Model No.

Model No.

AX050-0180

AX050-0180

|

Capacity (lbs)

Capacity (kgs)

100,000

45,359

|

Base Diameter (in)

Base Diameter (mm)

180

4,572

|

Top Diameter Min (in)

Top Diameter Min (mm)

180

4,572

|

Top Diameter Max (in)

Top Diameter Max (mm)

216

5,486

|

Caster Diameter (in)

Caster Diameter (mm)

30

762

|

Height (in)

Height (mm)

13

330

|

Air Flow (scfm)

Air Flow (l/m)

114

3228

|

|

Model No.

Model No.

AX050-0114

AX050-0114

|

Capacity (lbs)

Capacity (kgs)

100,000

45,359

|

Base Diameter (in)

Base Diameter (mm)

144

3,658

|

Top Diameter Min (in)

Top Diameter Min (mm)

144

3,658

|

Top Diameter Max (in)

Top Diameter Max (mm)

180

4,572

|

Caster Diameter (in)

Caster Diameter (mm)

30

762

|

Height (in)

Height (mm)

13

330

|

Air Flow (scfm)

Air Flow (l/m)

114

3228

|

|

Model No.

Model No.

AX050-0192

AX050-0192

|

Capacity (lbs)

Capacity (kgs)

20,000

9,072

|

Base Diameter (in)

Base Diameter (mm)

192

4,877

|

Top Diameter Min (in)

Top Diameter Min (mm)

192

4,877

|

Top Diameter Max (in)

Top Diameter Max (mm)

216

5,486

|

Caster Diameter (in)

Caster Diameter (mm)

24

610

|

Height (in)

Height (mm)

10.5

267

|

Air Flow (scfm)

Air Flow (l/m)

66

1869

|

|

Model No.

Model No.

AX050-0168

AX050-0168

|

Capacity (lbs)

Capacity (kgs)

20,000

9,072

|

Base Diameter (in)

Base Diameter (mm)

168

4,267

|

Top Diameter Min (in)

Top Diameter Min (mm)

168

4,267

|

Top Diameter Max (in)

Top Diameter Max (mm)

192

4,877

|

Caster Diameter (in)

Caster Diameter (mm)

24

610

|

Height (in)

Height (mm)

10.5

267

|

Air Flow (scfm)

Air Flow (l/m)

66

1869

|

|

Model No.

Model No.

AX050-0120

AX050-0120

|

Capacity (lbs)

Capacity (kgs)

20,000

9,072

|

Base Diameter (in)

Base Diameter (mm)

120

3,048

|

Top Diameter Min (in)

Top Diameter Min (mm)

120

3,048

|

Top Diameter Max (in)

Top Diameter Max (mm)

144

3,048

|

Caster Diameter (in)

Caster Diameter (mm)

20

508

|

Height (in)

Height (mm)

10.5

267

|

Air Flow (scfm)

Air Flow (l/m)

48

1359

|

|

Model No.

Model No.

AX050-0096

AX050-0096

|

Capacity (lbs)

Capacity (kgs)

20,000

9,072

|

Base Diameter (in)

Base Diameter (mm)

96

2,438

|

Top Diameter Min (in)

Top Diameter Min (mm)

96

2,438

|

Top Diameter Max (in)

Top Diameter Max (mm)

120

3,048

|

Caster Diameter (in)

Caster Diameter (mm)

20

508

|

Height (in)

Height (mm)

10.5

267

|

Air Flow (scfm)

Air Flow (l/m)

48

1359

|

|

Model No.

Model No.

AX050-0144

AX050-0144

|

Capacity (lbs)

Capacity (kgs)

20,000

9,072

|

Base Diameter (in)

Base Diameter (mm)

144

3,658

|

Top Diameter Min (in)

Top Diameter Min (mm)

144

3,658

|

Top Diameter Max (in)

Top Diameter Max (mm)

168

4,267

|

Caster Diameter (in)

Caster Diameter (mm)

20

508

|

Height (in)

Height (mm)

10.5

267

|

Air Flow (scfm)

Air Flow (l/m)

48

1359

|

Back to Turntables

Back to Turntables

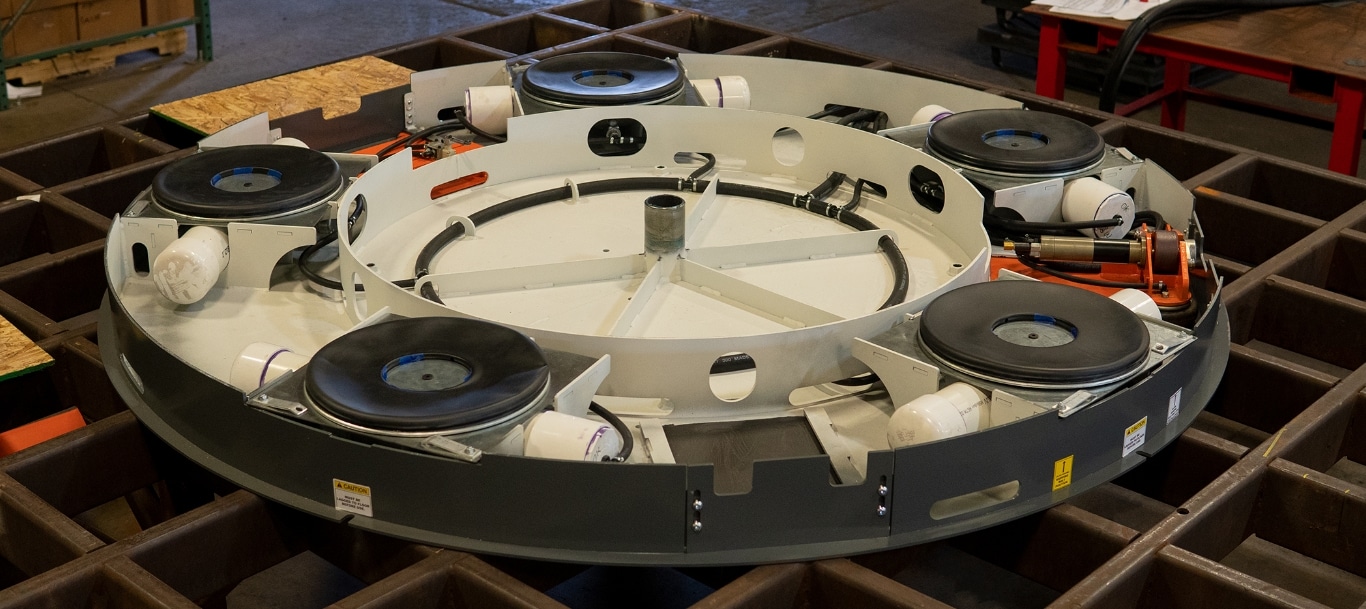

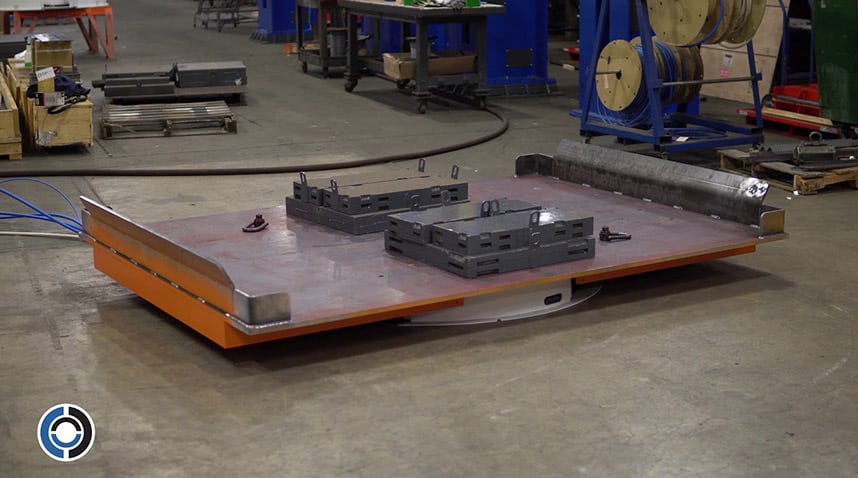

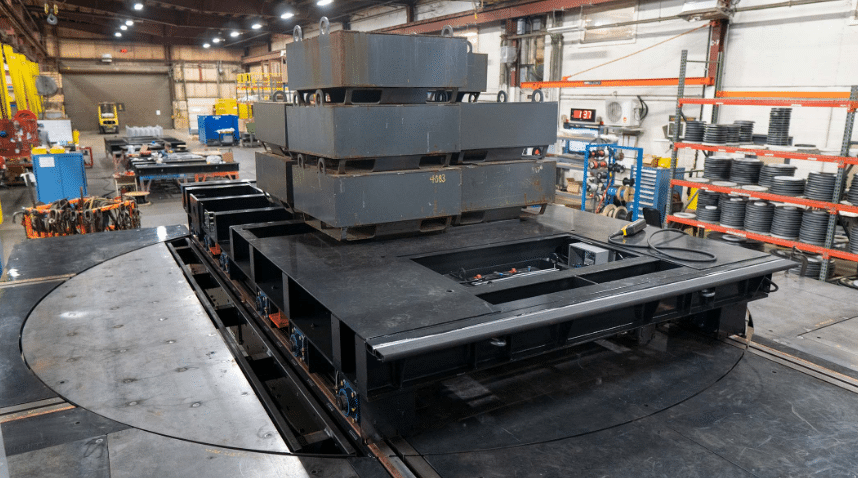

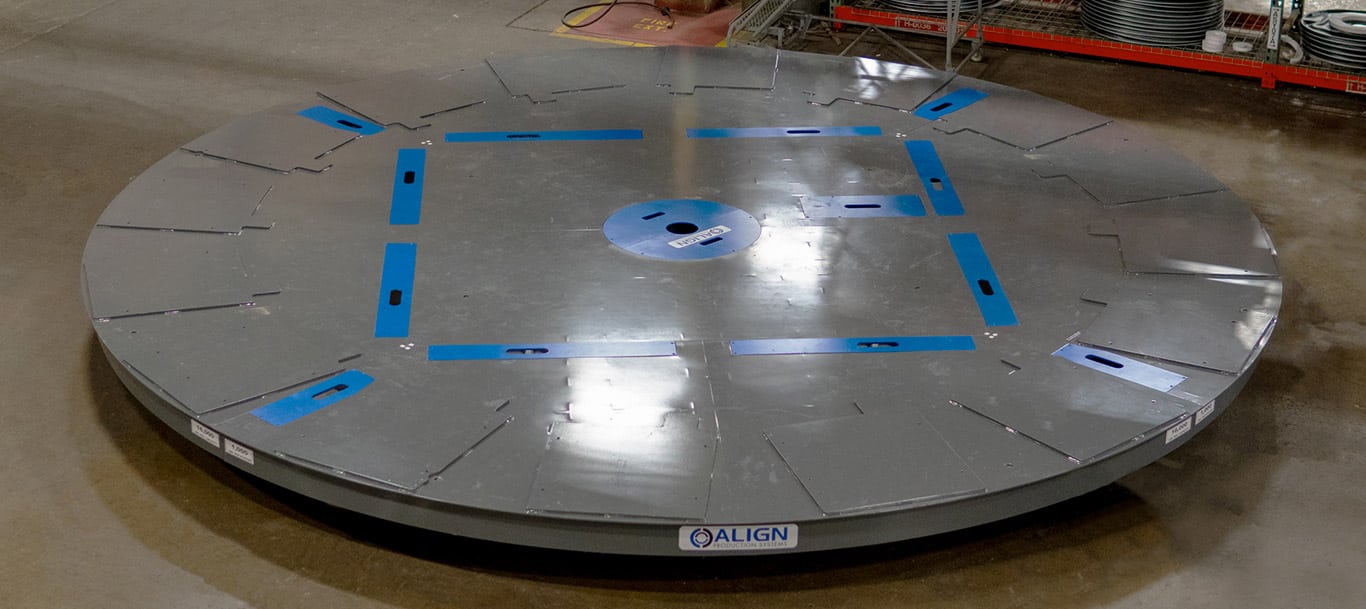

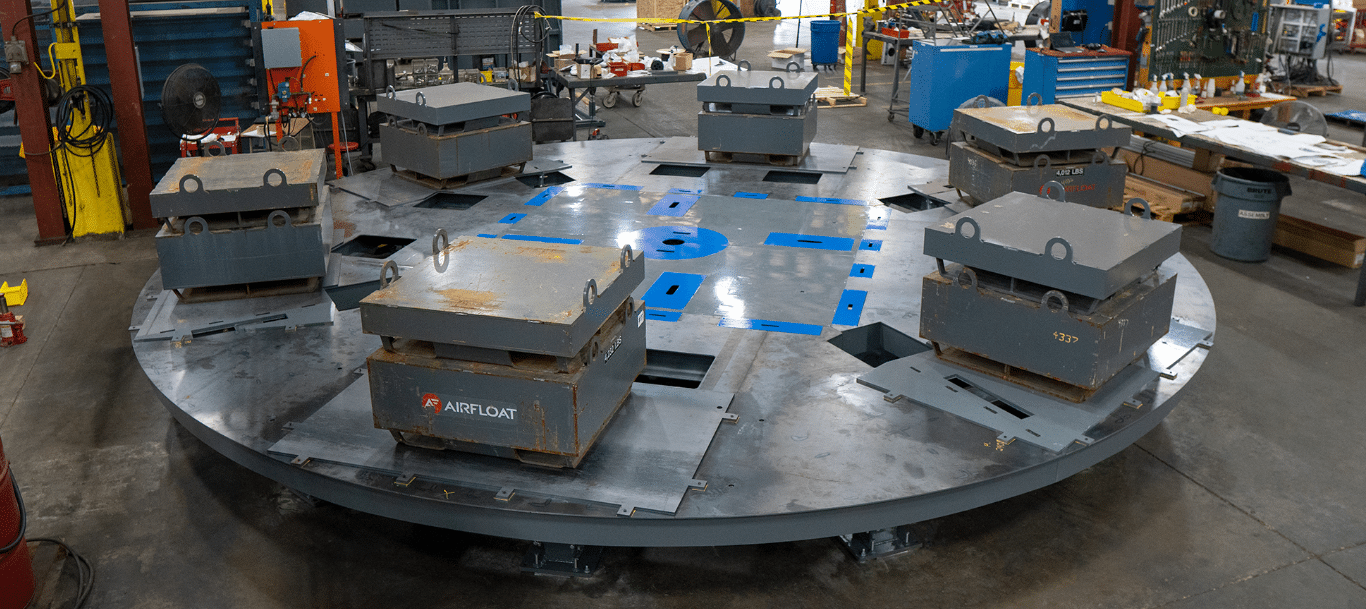

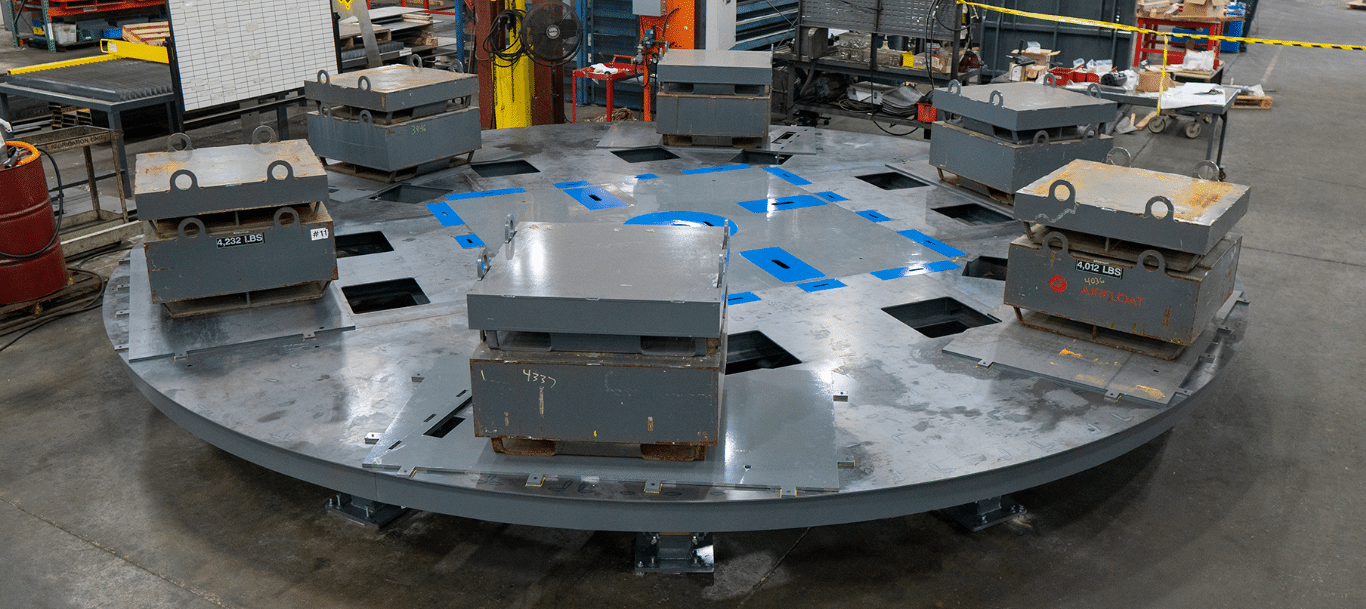

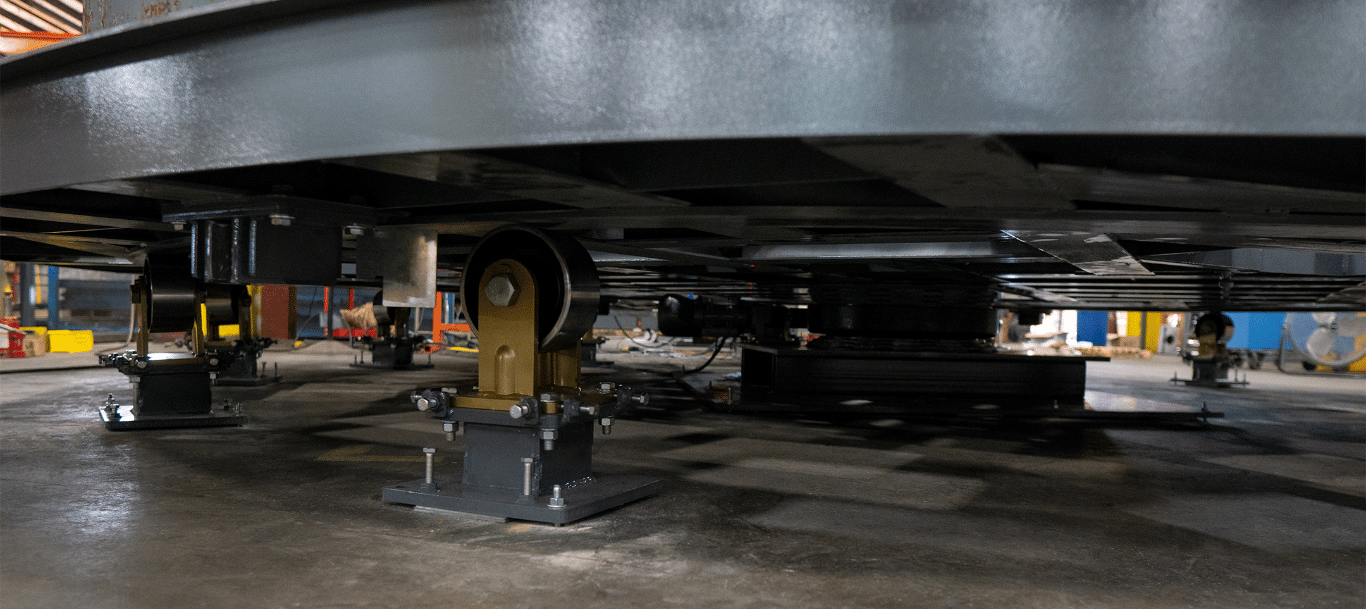

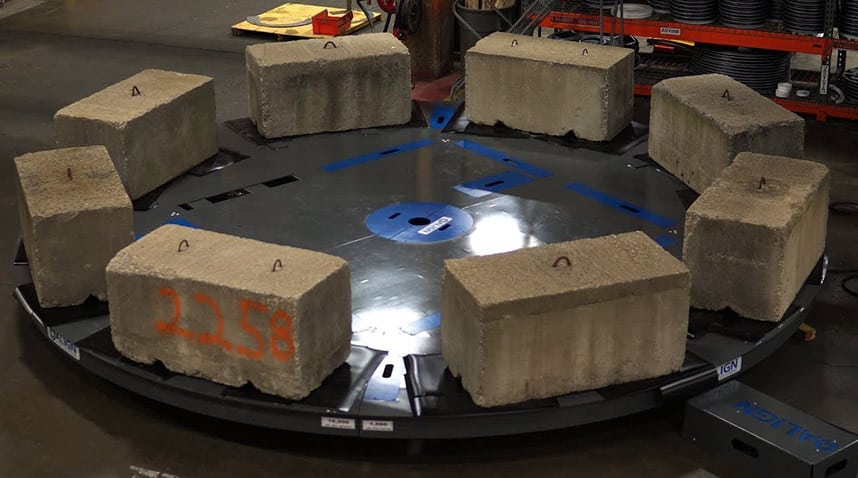

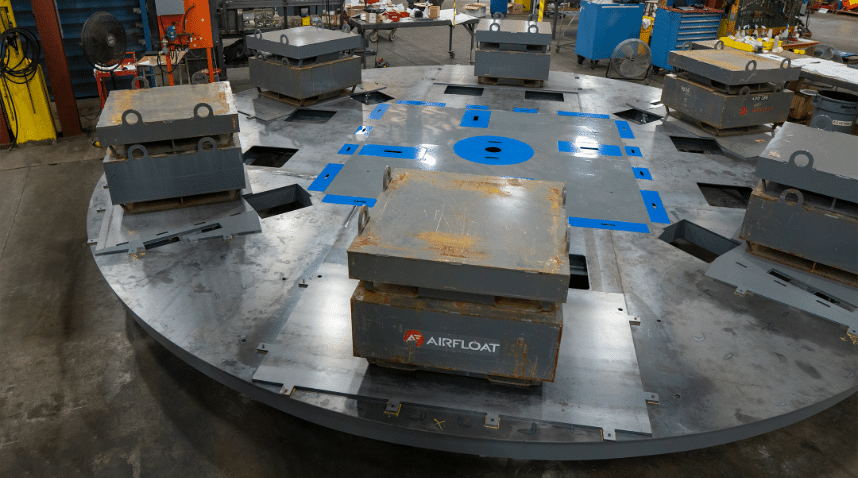

Round Air Caster Turntables

Round Air Caster Turntables